NormVolume

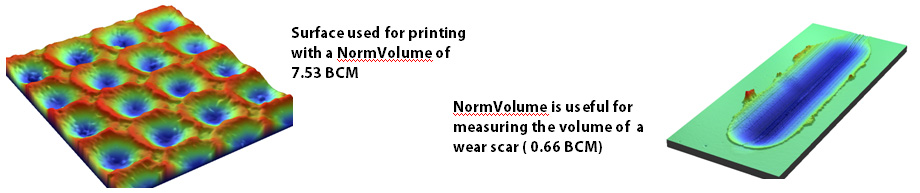

NormVolume, the Normalized Surface Volume, is found by calculating the volume contained by the surface and a “plane” that is placed near the top of the surface. The placement of the reference plane is done on a statistical basis to ensure that the very high peak locations are not used as the reference point for the plane. Once the volume is calculated (e.g. in units of cm3), the volume result is “normalized” to the cross sectional area of the plane (e.g. units of m2). Other units of NormVolume are BCM which is an acronym for “Billions of Cubic Microns per Inch Squared”. The BCM units are typically used in the printing industry.

Application

NormVolume finds application in the printing industry, by providing a measure of the fluid holding properties of printing device surfaces (e.g. anilox rolls, Lithoplates, etc. ) and the printed media (e.g., paper). Other applications, such as in the tribology field use the NormVolume to establish the volume of space a surface provides for lubricant containment. The measurement of various wear patters may result in a structure in which NormVolume may quantify the amount of material removed from a surface or displaced along a surface.