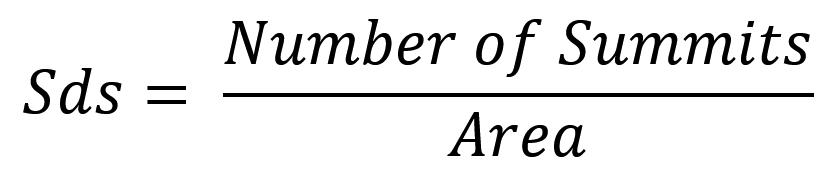

Sds, the Summit Density, is one of the so-called “Hybrid” surface texture parameters. Sds counts the number of summits per unit area of the surface. The summits are derived from “peaks,” which are defined as any point that is higher than all 8 of its nearest neighbors.

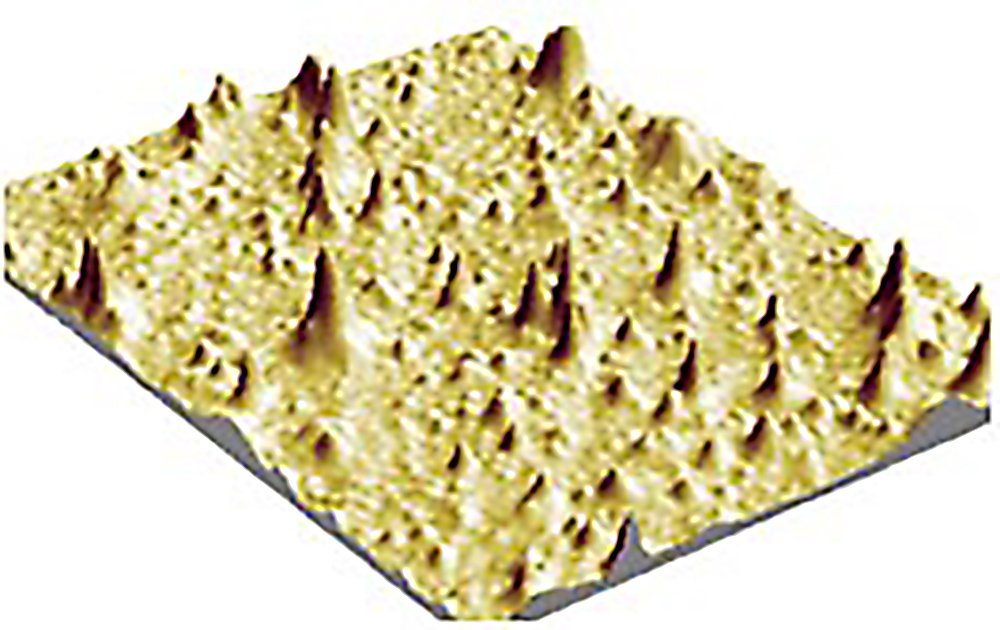

To calculate Sds we add a couple of additional constraints. First, we want to make sure that we only count closely spaced peaks as a single summit, to limit the effect of local spikiness. We do this by only including peaks that are separated by at least 1% of the X or Y dimension of the measurement area, whichever is smaller. Second, we want to only include peaks of substantial size; therefore, we set a height threshold at 5% of Sz (the root-mean-square roughness) above the mean plane, and we only count peaks that exceed that threshold. These two constraints help remove noise and outliers so that we have a more repeatable measure of the density of high points on the surface.

The manner in which the summits elastically and plastically deform under load is related to the Sds parameter, so it is a key parameter for controlling surfaces used in applications such as bearings, seals and electronic contacts. Depending on the application, a low Sds may result in higher localized contact stresses, possibly leading to pitting and debris generation. In applications involving sliding components, a number of summits are needed to prevent optical contacting while simultaneously maintaining a reasonable load distribution. Summit density may also be related to the cosmetic appearance of a surface once painted.

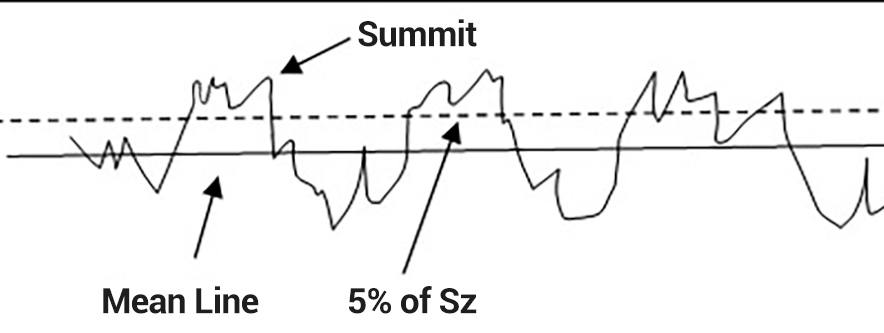

The image below shows a 3D optical profiler measurement of a plastic film used in the packaging industry. The asperities are desired and are carefully controlled to prevent the film from sticking to itself on the roll, or to the items it is intended to protect. The field of view is 238 µm x 181 µm, and the measured Sds is 5270 / mm2.

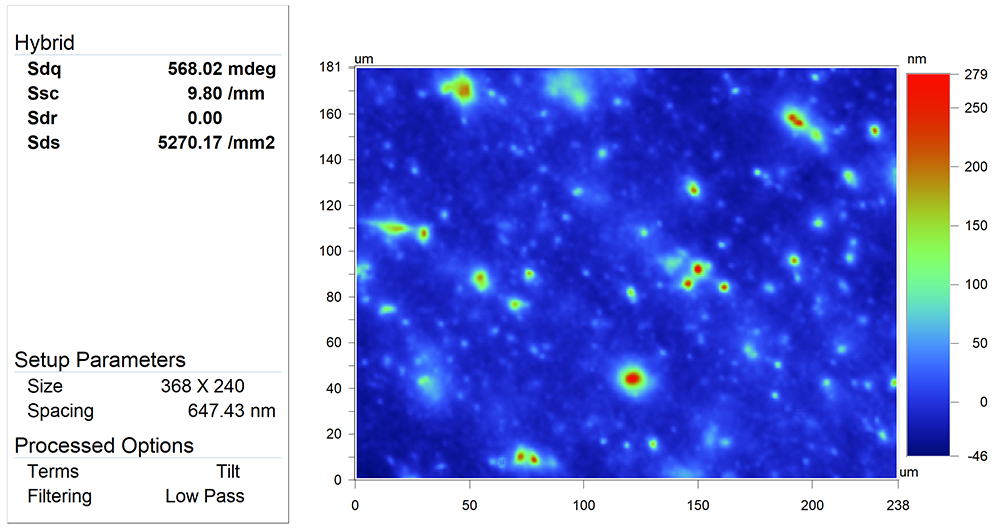

Here is the surface presented as a 3D, false color map. The monochrome palette helps to highlight the summits.

Note that Sds is not strictly defined in the ANSI ISO 25178-2 specification for surface texture parameters. It was, however, established earlier in the research which contributed to ISO 25178-2. Future sections of ISO 25178-2 may address parameters such as Sds as “Feature Parameters.”

Interested in applications for Sds and the other Hybrid parameters? Read more in the Texture Parameters Glossary