Wear is a progressive modification to a surface. It’s not necessarily a process of removal, however—material may also be redistributed, or even added, depending on the wear mechanism.

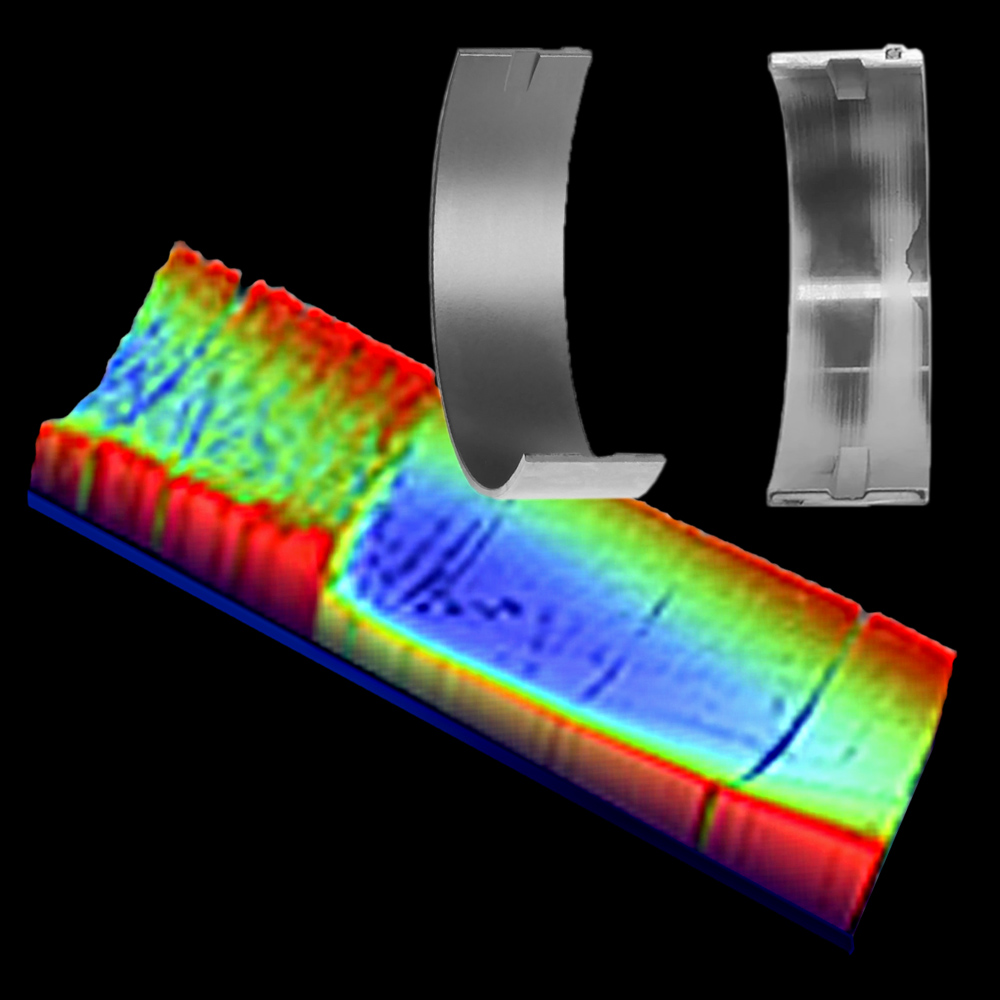

Surface roughness measurement can be used to quantify wear throughout a component’s lifetime. Using an optical profiler, large field-of-view, 3D (areal) surface data can be acquired. The depth, width, volume, and texture of wear scars can then be measured and tracked, as well as changes in surface roughness or other wear characteristics.

Michigan Metrology has been measuring wear for over 25 years. We help solve issues related to wear, both in production and after a part has seen service.

Issues we address: