Measuring surface roughness in 3D can offer a host of benefits. But for many companies, a measurement system may not be in the near-term budget. Here’s a way to reap the benefits of 3D measurements while you pursue you own 3D optical profiler.

What can optical 3D measurement give me (that a stylus can’t)?

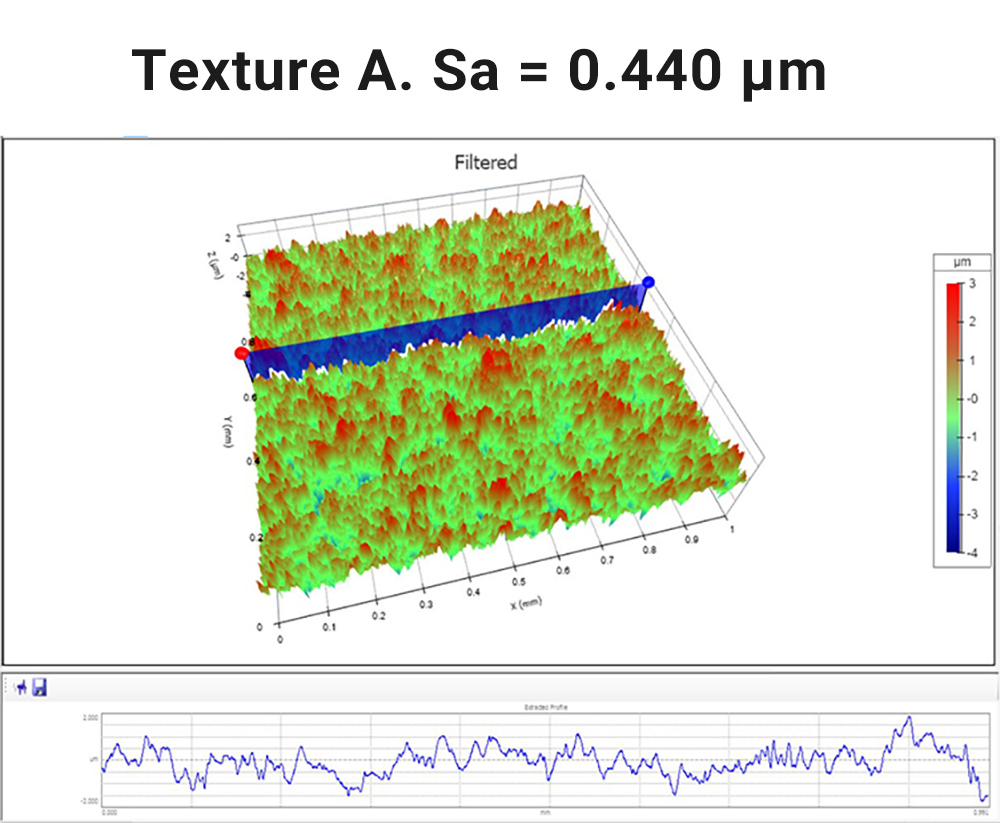

Stylus profilometers have been used for decades to obtain numerical roughness data or, in some cases, a 2D measurement of the trace. A single profile measurement, however, offers only a limited view of the surface. Texture may be dramatically different just millimeters (even microns!) away from the measured trace, and even at an angle to the trace. Pits, porosity, and other “areal” aspects of the texture simply cannot be detected or measured from a single profile.

3D data makes it possible to visualize texture—an important aid for diagnosing quality issues and improving processes. The millions of measured points offer an unprecedented level of data to describe a surface. Because optical systems are non-contact, virtually any material can be assessed without damage from a profilometer’s sharp probe. What’s more, modern systems like the Bruker NPFlex can measure texture in locations that a stylus cannot reach, even on large components or systems.

A 3D optical texture measurement (center) can provide far more information than just a numerical value (top) or a 2D profile (bottom)

Outsourcing 3D measurement is economical

Outsourcing measurements to a third-party lab can make 3D measurement data accessible. Michigan Metrology provides small-batch 3D surface roughness measurements to verify new processes and to troubleshoot product development issues. We also provide ongoing measurements for parts that are already in production.

Michigan Metrology’s contract measurement lab is an integral part of many companies’ supply chains.

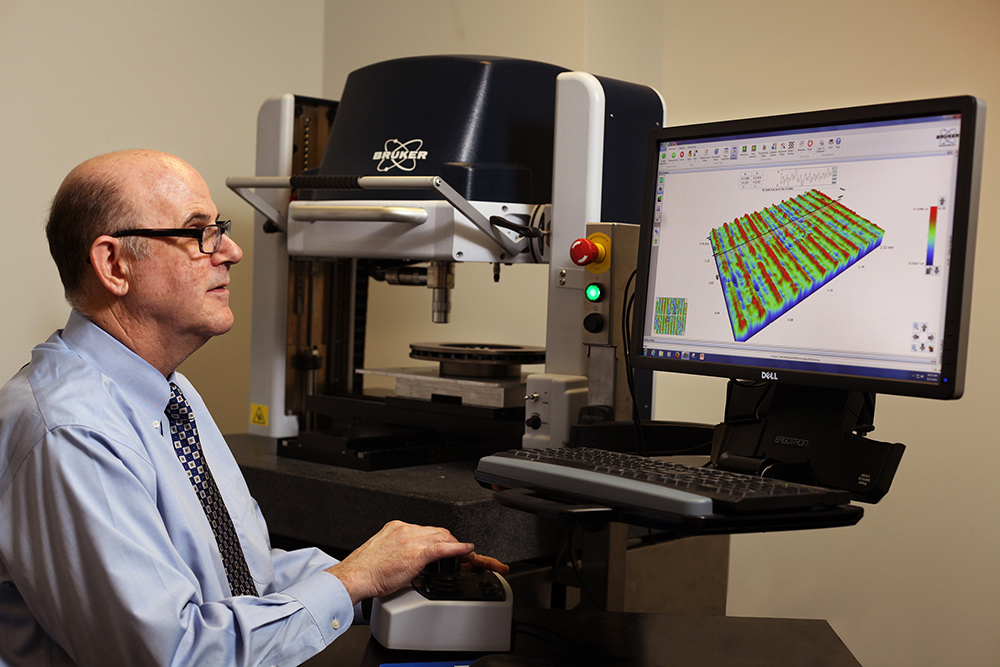

Equipment yes…but expertise as well

A third party metrology lab can offer specialized expertise as well as equipment, to help solve production or quality issues as well as to measure parts. As a Bruker Value-Added Partner, Michigan Metrology works with many regional and national manufacturers who leverage our metrology expertise to maintain and improve their processes. Our midwestern location (in Livonia, Michigan) lets us ship parts quickly throughout the Midwest and across the country, making us a reliable part of many companies’ supply chains.

Michigan Metrology’s measurement lab offers decades of expertise as well as reliable 3D surface texture measurements

Find out how Michigan Metrology can help you reap the benefits of 3D surface roughness measurement, economically!