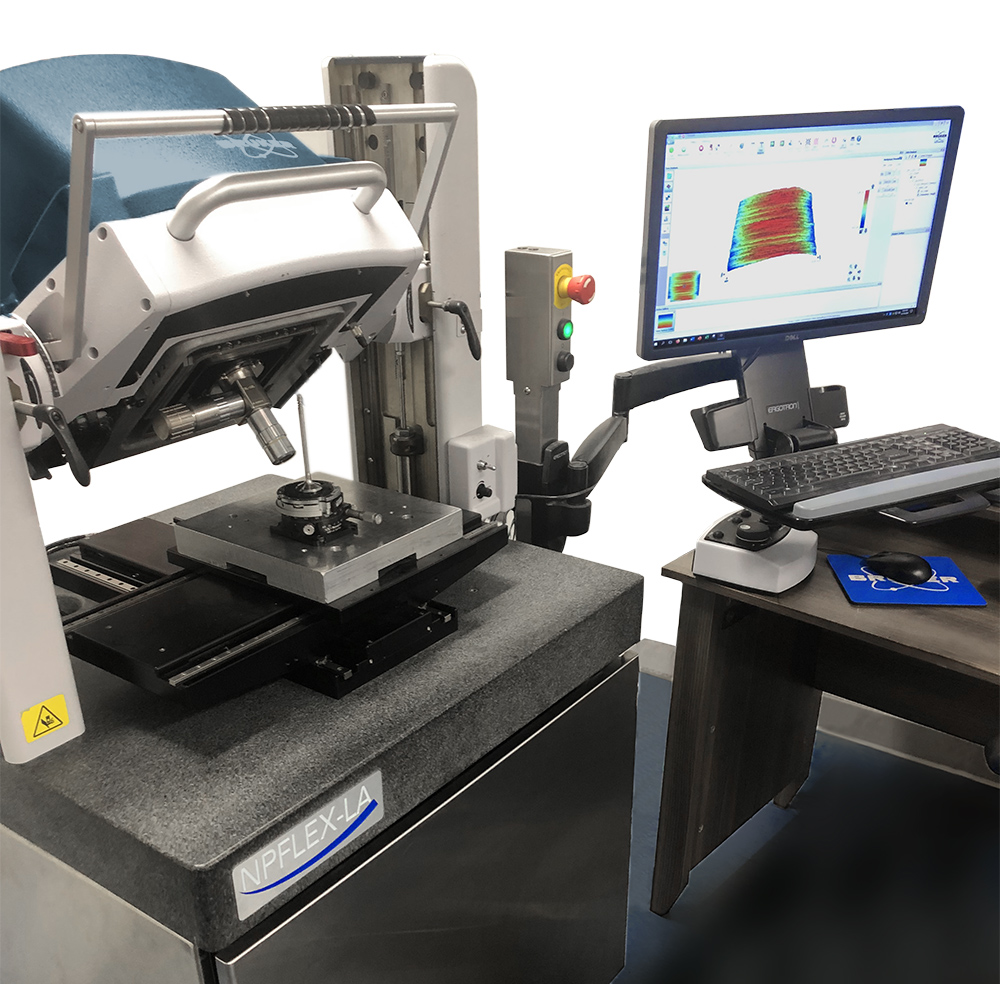

Through Michigan Metrology’s 30 years in business, we’ve owned many generations of 3D surface texture measurement instruments. For the past 10 years we’ve been lucky to have what we consider the “gold standard,” and that’s the Bruker NPFlex 3D Optical Profiler. So, why are we such fans?

The Bruker NPFlex gives our lab a huge amount of measurement capability.

Measure…just about anything

As you can imagine, we measure lots of different types of components here, from heart stents to brake rotors. The NPFlex has a range of objectives and accessories that let us quickly adapt the system for very different measurements.

Measure difficult-to-access areas

We frequently need to measure texture inside, under, and around part features. This valve face measurement is a good example:

Measuring this valve face would be challenging on many measurement systems…

Making this measurement with a stylus would require some fixturing and would only net a single radial trace. On most optical systems, the valve stem may obstruct the measurement head and make it hard to measure.

The NPFlex is the only system that we know of with a tiltable head, which lets us square the measurement axis to the test surface. That tilting head, plus long working distance objectives, let us clear obstructions and measure the locations we need to access.

…but the tilting head and long working distance objectives on the Bruker NPFlex make it easy.

With a rotational stage, like the one shown in the image above, we can simply set the valve in place, then rotate the stage to measure all the way around its perimeter. That’s incredibly helpful for measurements like this, as well as for small, complex parts such as medical implants.

Measure large parts

We’ve been able to measure some very large and cumbersome parts on the NPFlex. We’ve accommodated parts up to 50 pounds (Bruker’s specs rate the weight capacity much higher), which comes in handy, especially in the Detroit area!

Excellent analysis software

Bruker’s 3D surface texture analysis software has been maturing since the early 90s and now includes a massive number of features.

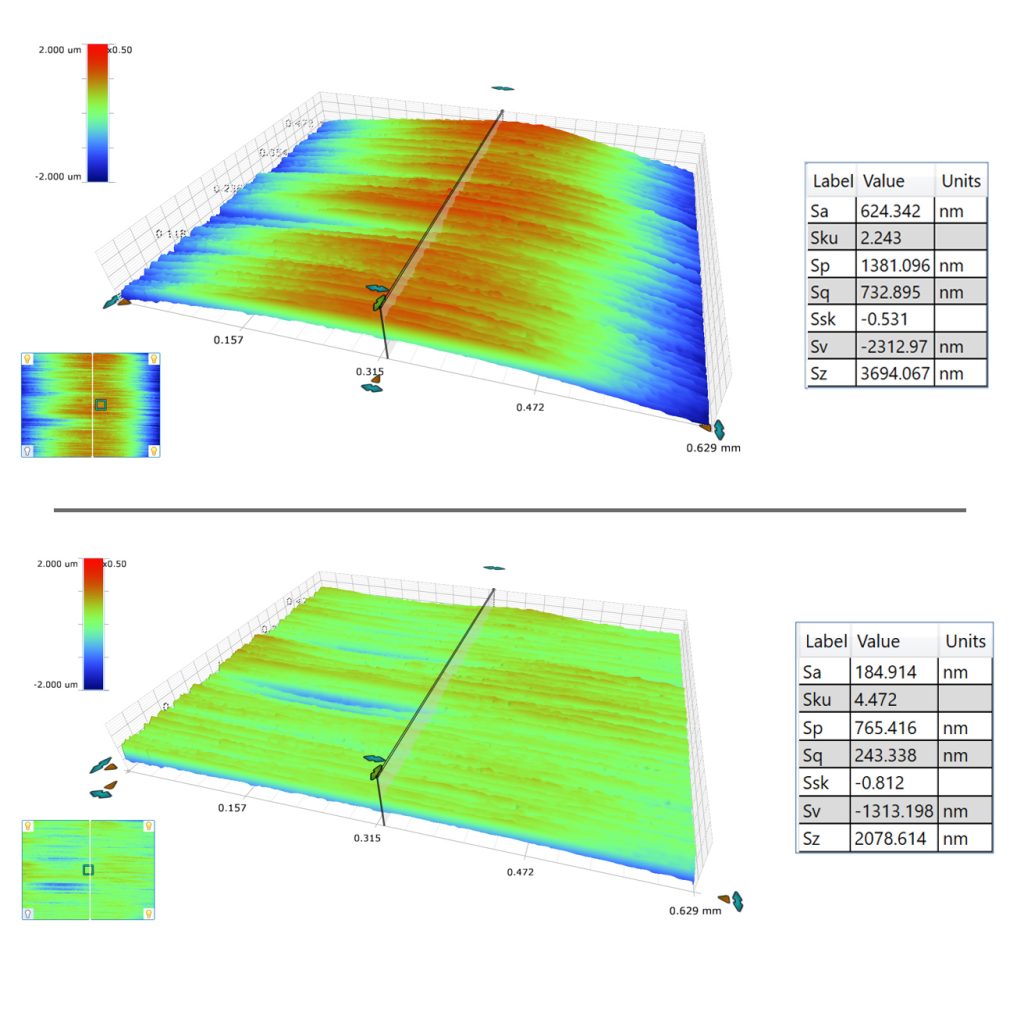

The valve seat measurement before and after curvature has been removed from the data.

Michigan Metrology owes much of its contract measurement success to excellent 3D surface texture measurement equipment like the Bruker NPFlex. Got a challenging measurement? Contact us to arrange a Teams meeting—we’d be glad to talk it through and see how we can help!