Surface texture plays a major role in sealing. But just making a surface “rougher” or “smoother” may not improve how well your surfaces seal.

Interested in a deep dive into surface roughness? Check out our in-person and online classes!

Average roughness may not tell you enough

We say it all the time: just measuring Ra (average roughness) may not give you enough information to predict whether a surface will leak or seal. Ra (or Sa for areal 3D measurements) does give a general sense of overall roughness, and it can indicate when a surface has changed. But it can’t distinguish peaks from valleys, indicate where peaks are on a surface, identify a predominant direction in the texture, or many other aspects that can lead to leaks. Ra is just a start if you need to predict sealing!

Average roughness alone may not tell you how a surface will function.

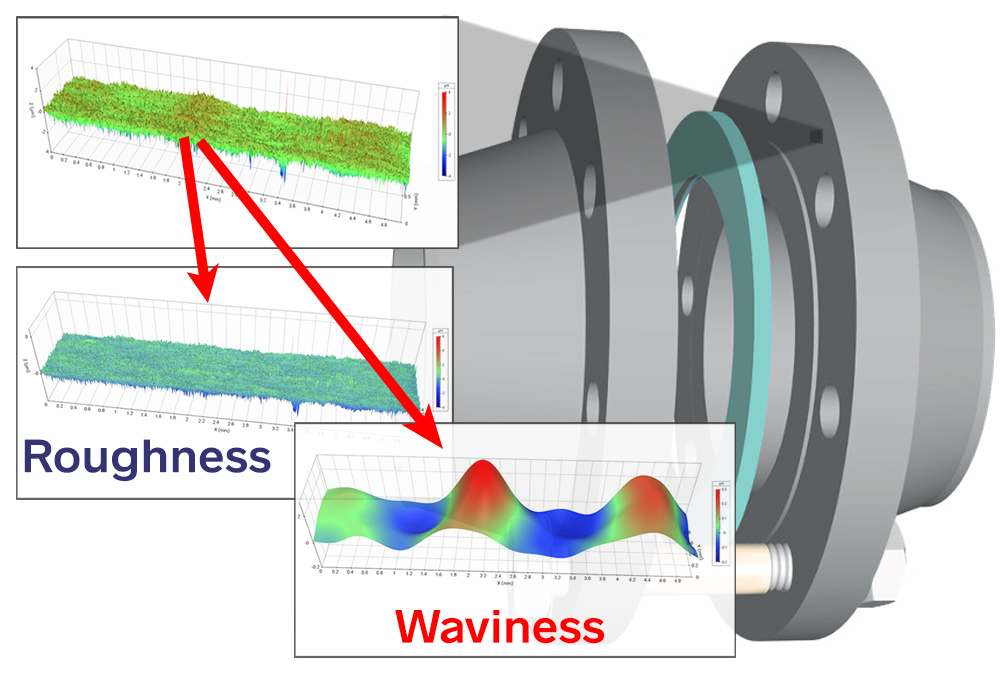

Waviness

While leaks can be due to surface roughness (the shorter spatial wavelength features in a surface), leaks can also be caused by waviness, the longer spatial wavelengths. Gaps can form when the undulations in a surface exceed what the mating surface can conform to—and those gaps can be large.

So, shouldn’t large gaps like these show up in Ra measurements? The answer is simply: No! We calculate Ra from the “roughness profile.” The roughness profile is calculated by filtering out the longer spatial wavelengths so that we can see and analyze the finer roughness. So, we calculate Ra after we’ve removed all those longer wavelengths! It’s like measuring the length of the grass over a series of hills…whether the grass is cut or not, the hills are still there, and Ra gives you no insight into how big they may be.

Measuring roughness excludes the longer spatial wavelengths of waviness, which can also cause leaks.

Texture parameters that respond to changes in waviness can help control these longer spatial wavelengths and make sure that the interface can achieve a good seal.

Read about waviness in our article, Noise may be hiding in the waviness

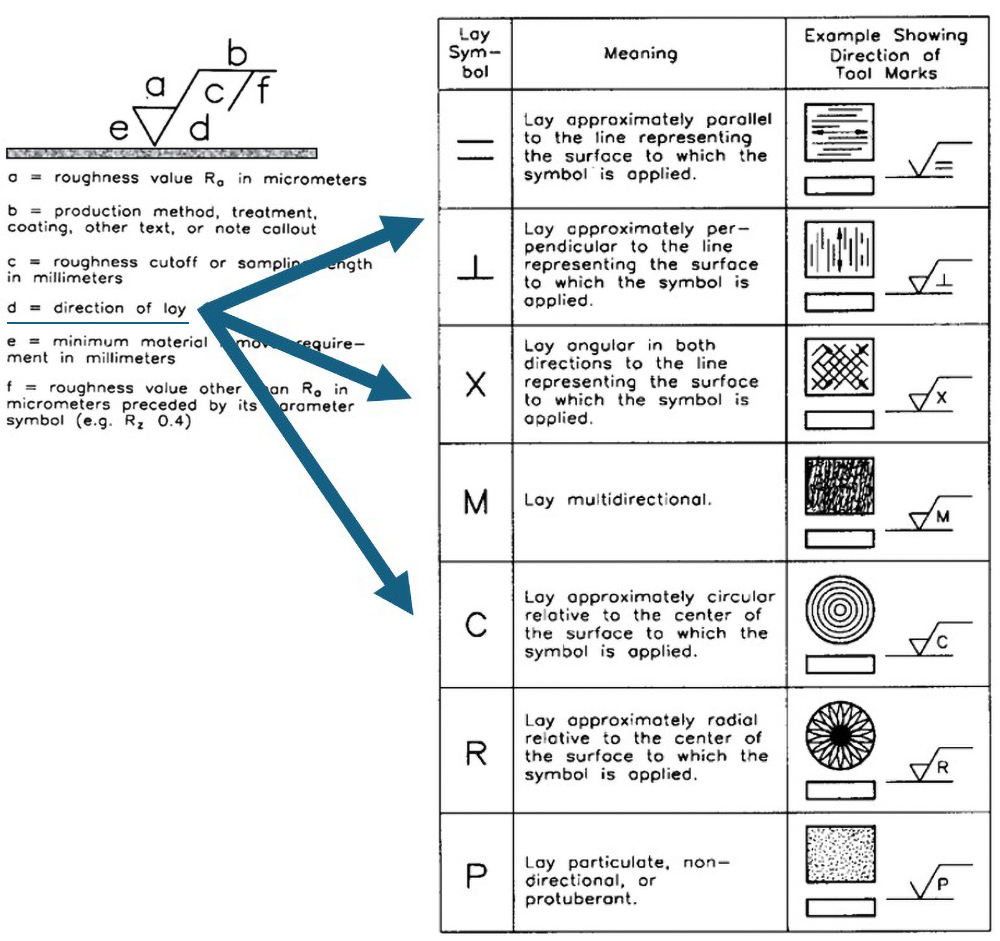

Directionality

Microtexture can have a predominant direction (i.e., lay) that can help or hinder fluid flow. If the direction of the lay is across a sealing interface, then the valleys in the texture can channel fluid through the interface. If the lay runs perpendicular to the leak direction, then the texture can oppose the fluid flow and limit or prevent leakage.

Specifications such as ASME Y14.36 include provisions for specifying the lay, as shown below.

The ASME Y14.36 specification includes provisions for specifying the lay.

Other surface texture parameters, such as Std (Texture Direction), may also be helpful to determine and control the lay.

Read more about the Std parameter in the Surface Texture Parameters Glossary

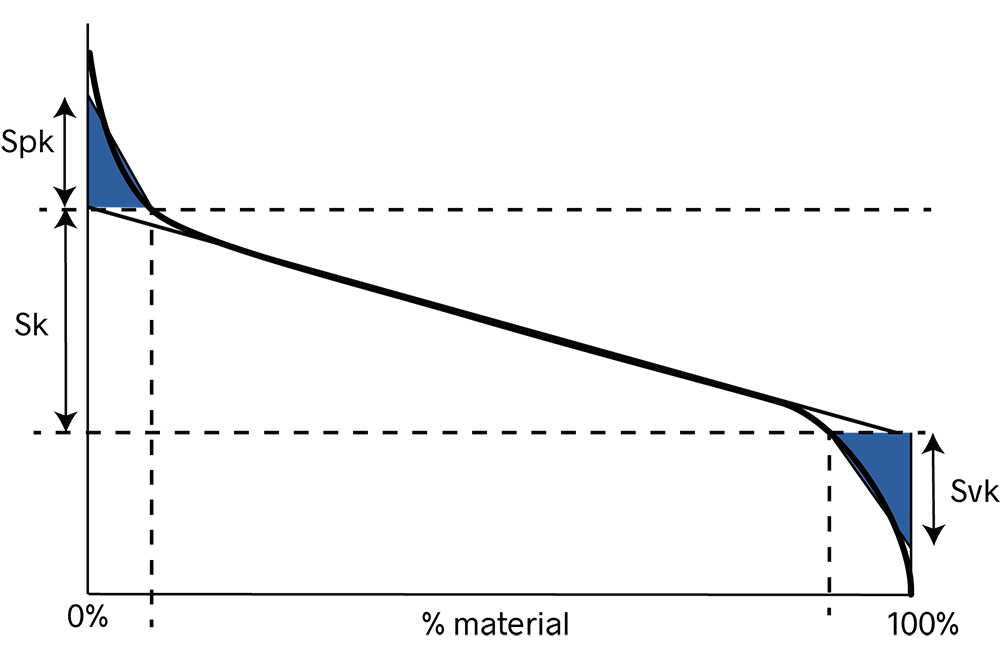

Plateaued surfaces

Engines and rotary equipment require surfaces that can slide and seal simultaneously. This difficult balance is often accomplished with “stratified” surfaces, which have a plateaued region for sliding and valleys to retain fluids. The balance is critical: the plateau must have just enough texture to reduce friction. At the same time, the angle and depth of the valleys will determine how much fluid is moving through the interface.

Many surface texture parameters have been developed to describe plateaued surfaces. The Material Ratio Curve lets us look at the amount of material at every depth. From this curve, we can derive a number of parameters (notably Spk, Svk, and Sk) which can tell us about the plateau region, the valleys, and the core material respectively. The ratios of these parameters can also provide stable indicators of how the surface will perform.

When surfaces are highly plateaued (i.e., have extremely distinct plateau and valley regions, the “Q” parameters, based on the material probability curve, are powerful tools for describing the peaks and valleys, and the position where the plateau region meets the valleys.

Listen to Lake Speed, Jr. of Total Seal Piston Rings and Ed Kiebler of Rottler manufacturing discuss plateaued surfaces and related surface texture parameters

We’ll be writing more about surface texture and sealing in the future. For, now, check out the articles, videos, and parameters glossary here at michmet.com for more information. You may also want to consider the Surface Roughness, Texture, and Tribology class, which is available online and is also held live each Spring.