When you’re thinking about the most engineered surfaces in a car, you may think of cylinder bores, clutches, brakes, etc. But we’d like to put one more item on your list: the dashboard.

If you put a piece of paper on your dash, the reflection in the windshield can completely blind you to the road beyond. A smooth dashboard would have a similar effect—which is why car manufacturers go to great effort to perfect their dashboards’ surface texture.

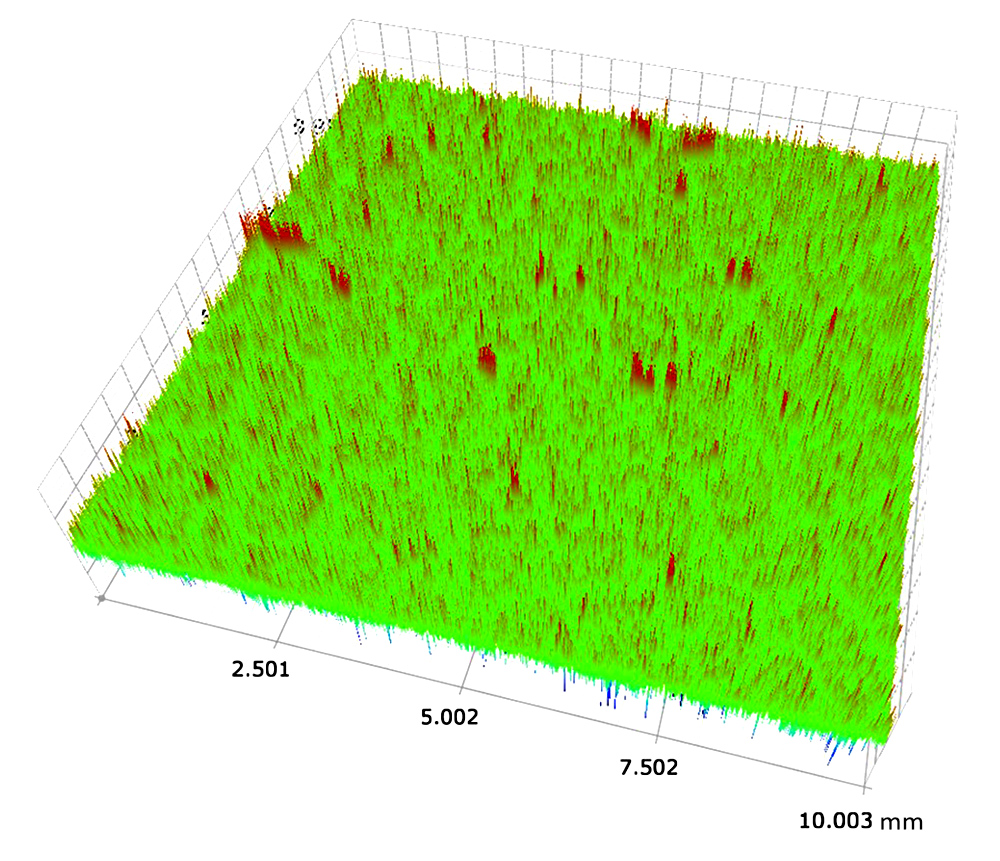

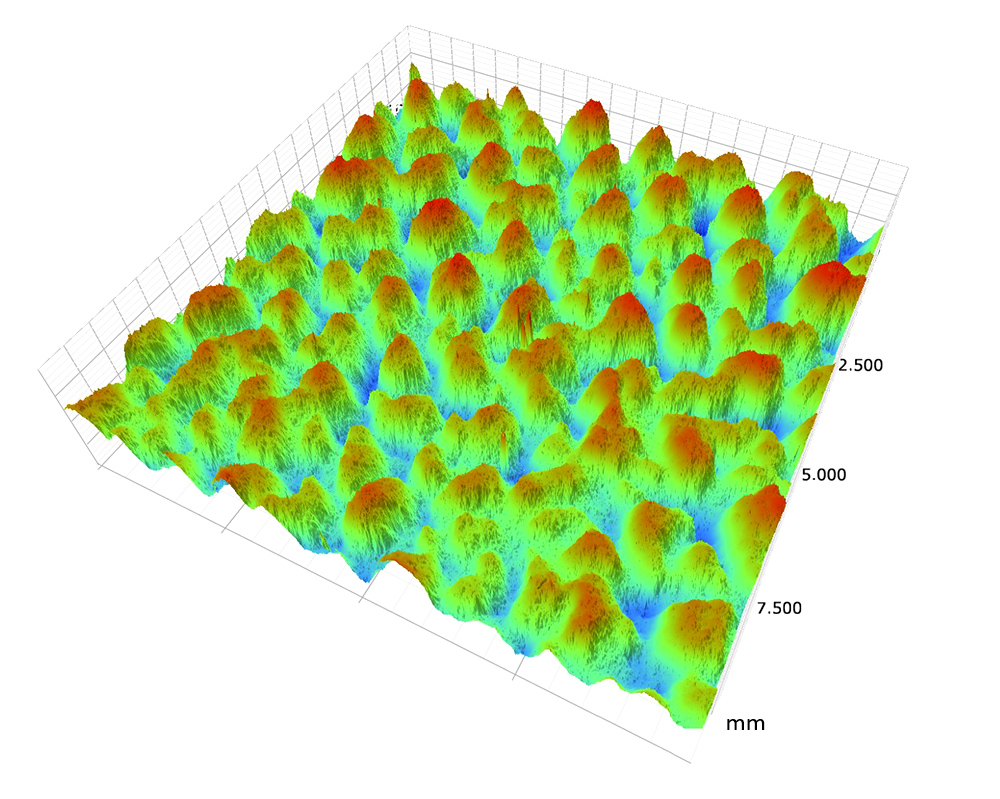

The first step is to add short spatial wavelength texture to the surface to scatter the light, which greatly cuts down on glare.

But light scattering isn’t the only consideration. Dashboards also have to withstand wear from drink and food containers, phones, feet, and all the other items that drivers place on the dash. These wear scuffs and scratches would be very obvious, and unattractive, if the surface only consisted of short spatial wavelengths.

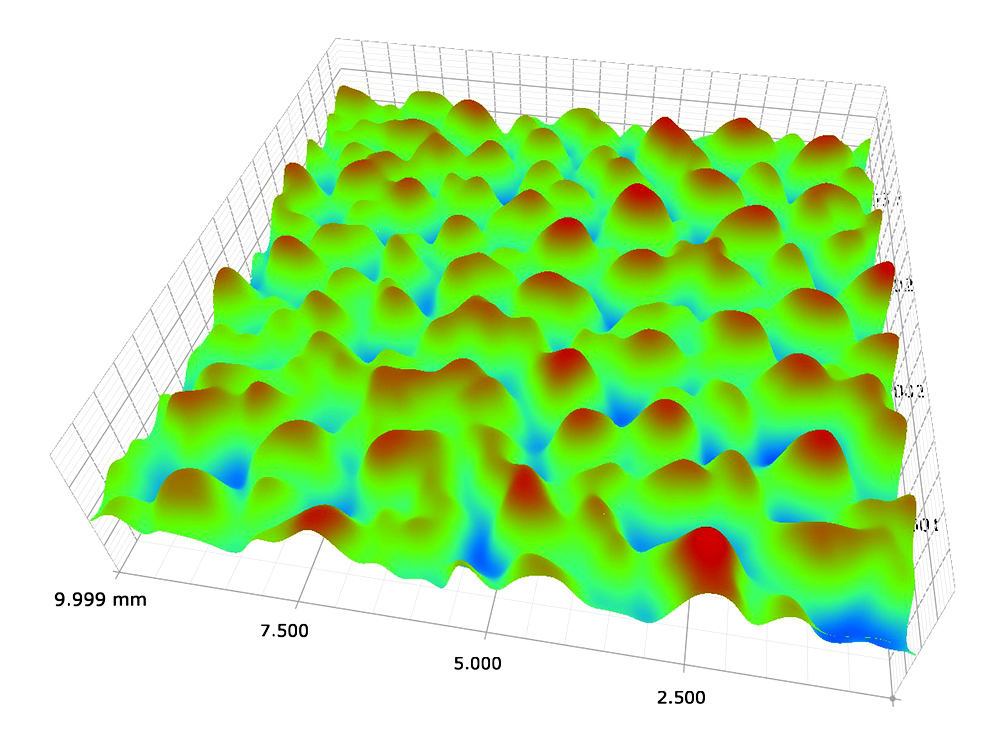

To minimize the effect of wear, manufacturers add longer spatial wavelength texture to the surface as well. The deeper, broader texture not only masks scratches and scuffs, but it also scatters light and even traps some of the reflected light in the crevasses.

The combined effect creates the “pleather” texture we see on most dashes, armrests, and kick panels.

So, when you’re considering the engineered surfaces in your car, don’t forget the one right in front of you. It’s a masterpiece of surface texture!

To learn more about controlling a surface’s appearance and wear characteristics, check out the many articles and videos in our Surface Roughness Analysis Blog.