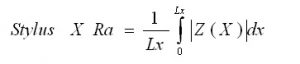

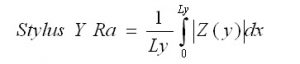

Stylus (X,Y) Ra

Stylus X Ra and Stylus Y Ra, the Average Roughness Along X and the Average Roughness Along Y, are found from the integral of the profiles along the respective directions:

Stylus (X, Y) Rt, the Maximum Profile Height Along (X,Y), is determined from the difference between the highest peak and lowest valley found along the evaluation length.

Stylus (X,Y) Rz, the Average Maximum Profile Height Along (X,Y), is derived from the average, over all cutoff lengths (i.e. sampling lengths), of the difference between the highest peak and lowest valley. Note, if the evaluation length equals the sampling length then the Stylus (X.Y) Rt and Stylus (X,Y) Rz values are equal.

Note that the value reported in the database is the average of all Stylus (X,Y) Ra, Rt, Rz values found over the 400+ profiles that comprise the 3D surface in the relevant direction.

Application

Stylus (X,Y) (Ra, Rt, Rz) may be useful in understanding any directionally dependent surface texture function. For example, a surface used for sealing may require a larger roughness average along the leak path direction (e.g. the X direction) and lower roughness average perpendicular (e.g. the Y direction) to the leak path for proper seal engagement.