Hone plates, or sharpening stones, are used to produce a fine edge on knives, scissors, and other tools. A kit of stones provides progressively finer grit sizes and spacings to provide an exquisitely sharp edge.

We recently had the opportunity to put a few of these stones under the microscope to have a look at the texture of their abrasive surfaces. The images below shows the coarse, medium, and fine surfaces, measured on our Bruker NPFlex 3D optical profiler.

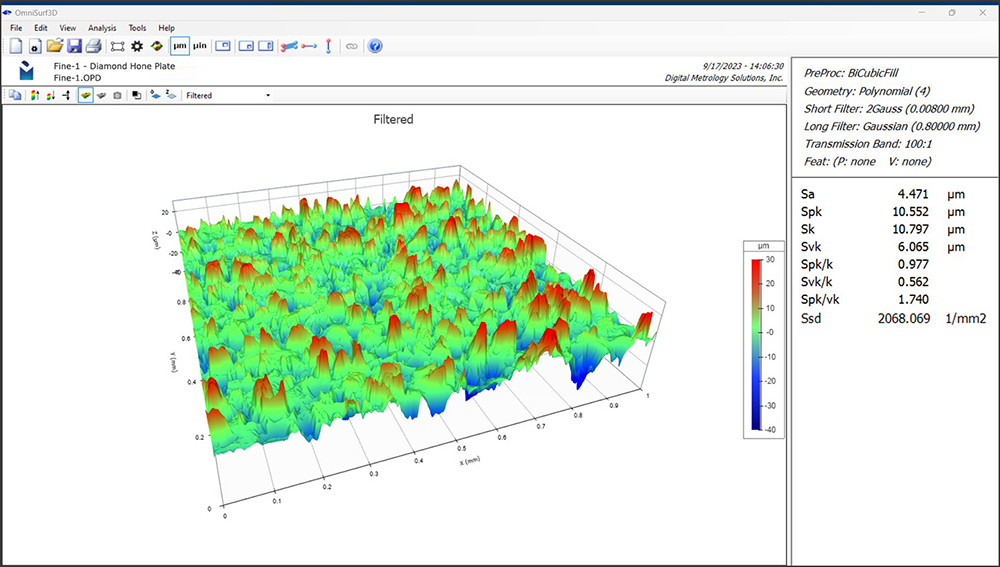

FINE

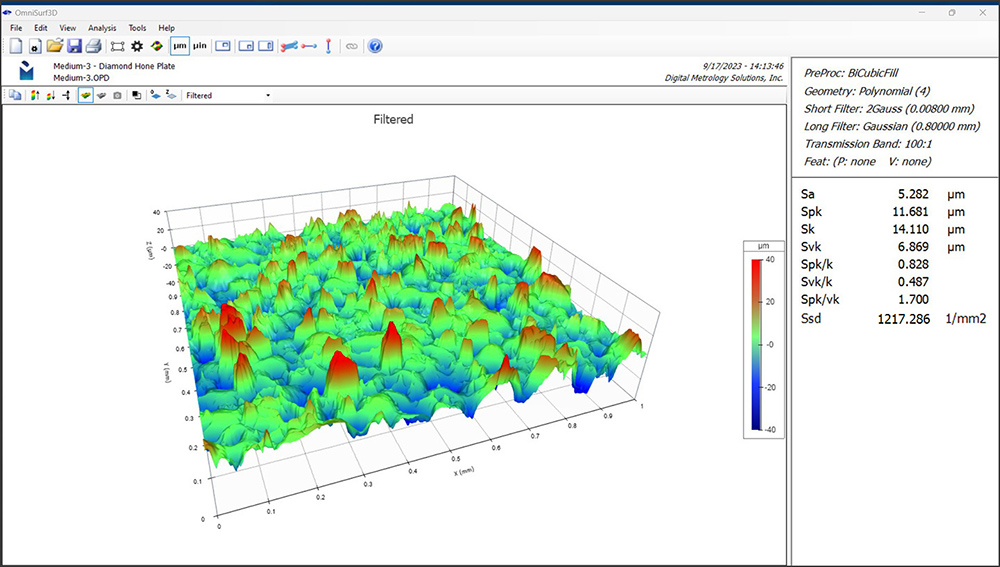

MEDIUM

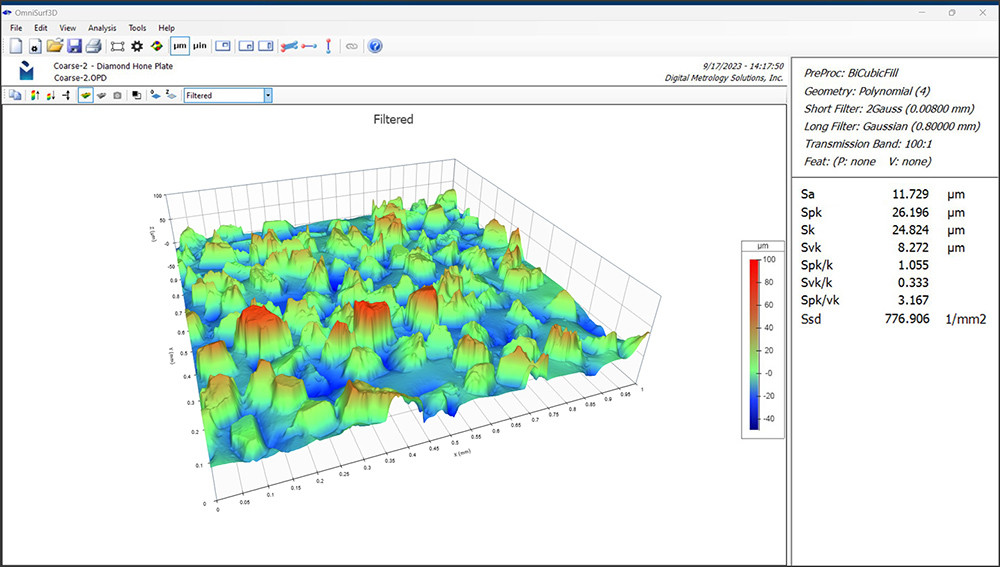

COARSE

Not surprisingly, the abrasive particles on the coarser grit surface are larger, both laterally and vertically. We can see this qualitatively in the images, but also quantitatively in the Sa (average roughness) values.

But there is more to the story than just the Sa values, which really measure just the amplitude of the roughness. Parameters such as Spk, Sk, and Svk might be important to tell us about the relative heights/depths of the peak, core, and valley regions in the surface.

The ratios between these parameters tell us about the symmetry of the surface. These parameters may be more stable indicators of whether the surface is consistent with a surface we know will perform well. For the abrasive surfaces, Spk/Sk (the ratio of the Reduced Peak Height to Core Roughness) might be useful for process control. Spk/Sk is very similar for the fine and medium grits but is much higher for the coarse stone (i.e., the surface is skewed toward the peaks).

The spacings between peaks and between particles may also be important for moving material away from the interface. Parameters that respond to changes in spacings, such as Ssd (Summit Density), might help us to differentiate a good surface from one that may clog up more quickly.

Understanding how surface texture parameters relate to performance is a key to maintaining processes and producing high quality surfaces. At Michigan Metrology we have been measuring surfaces like this for almost 30 years. Find out how we can help you with your measurement needs. Learn more on our Services page.

Want to know more about surface texture parameters? Download our Surface Texture Parameters Glossary.

Thanks to Dewey Sims for providing these samples.