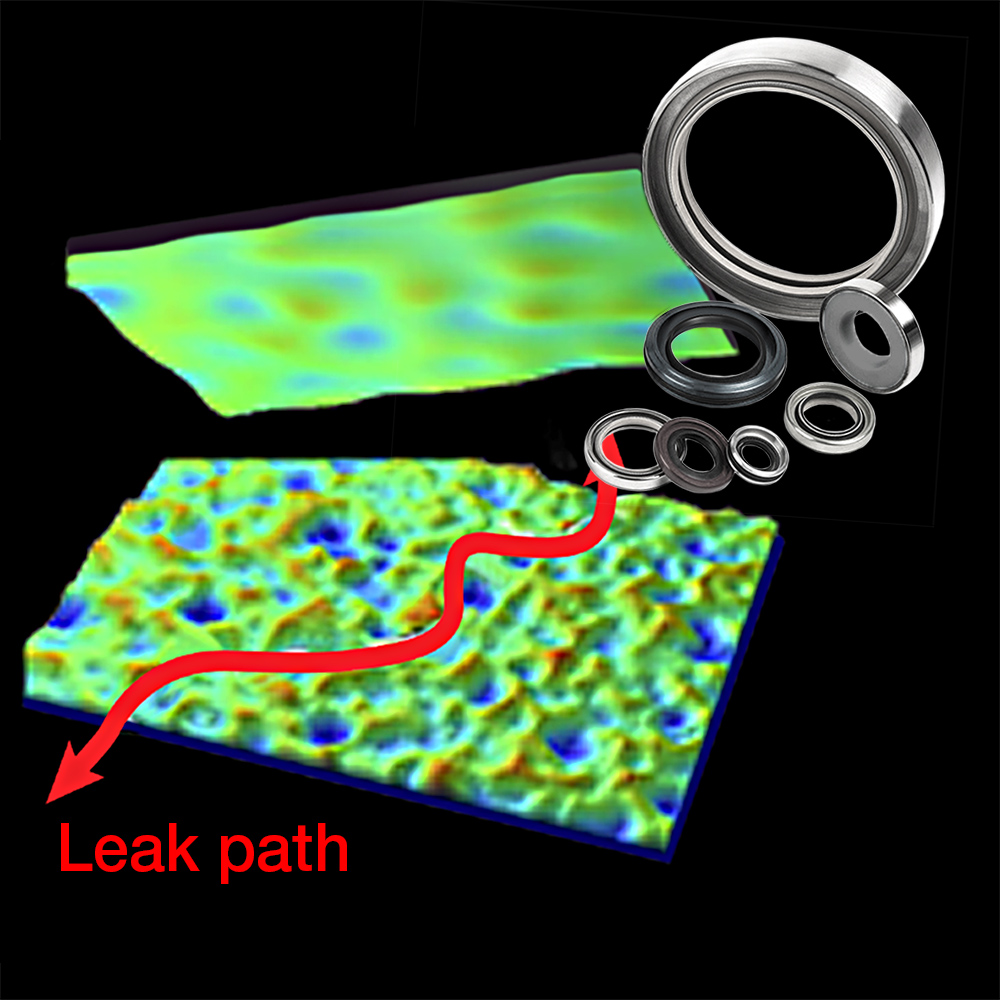

Areal (3D) measurements helps us quantify aspects of surface texture that is difficult, or impossible, to gain from 2D stylus measurements. Leak paths, for example, only become apparent when we can visualize and analyze an area of the surface.

But 3D data is just the beginning—we also need to track the right parameters to find and control potential leak paths. Average Roughness is not always the best predictor of whether two mating components will seal or leak. Other surface roughness parameters such as Texture Spacing (Rsm), Structure Complexity (Str, Sal) may describe the sealing surfaces better. Texture Amplitude Distribution, as measured by bearing area (Spk/Sk, Svk/Sk) is another option.

Issues we address: