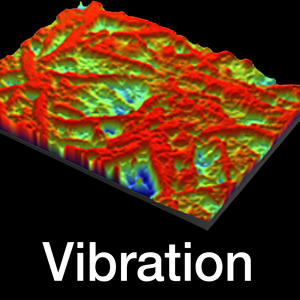

Decreasing Vibration

Shudder in a car’s brakes or steering mechanism can give an impression of poor quality. But far more than just an annoyance, vibrations in cars, industrial machinery, and aircraft components can lead to premature wear and, potentially, component failure. In many instances, close inspection of the surface roughness of mating components can uncover the sources—and … Read more