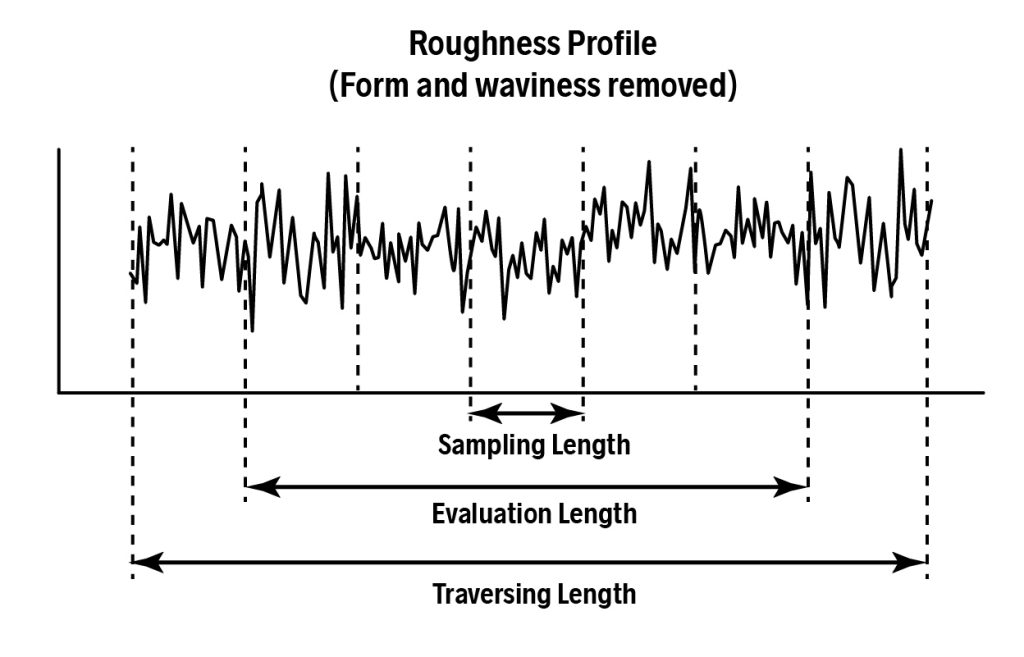

When measuring roughness with a stylus-based system you’ll hear the terms “traversing length,” “evaluation length” and “sampling length.” It’s important to understand their specific meanings and to adhere to them as specified on drawings in order to get accurate measurement data.

These three lengths are usually defined from shortest to longest.

A sampling length is defined based on the longest spatial wavelength that will be measured. It is also called a cutoff length because it equals the spatial wavelength of the “cutoff filter.” The cutoff filter separates shorter-wavelength roughness from longer-wavelength waviness.

The sampling length will be determined based on the spatial wavelengths that matter for a particular application. A typical cutoff wavelength (and thus sampling length) is 0.8 mm for roughness measurements. It’s important to note that this is not a hard-and-fast value; it should be defined based on the roughness requirements for the particular surface.

The evaluation length, or assessment length, is the part of the stylus trace that will be used to calculate parameters. The evaluation length is typically specified based on some number of sampling lengths (five sampling lengths is typical for roughness parameters). It can also be specified as an integral number of sampling lengths (e.g., “Ra8” specifies eight sampling lengths) or as an absolute length.

The traversing length, or tracing length, is the entire distance that the stylus must travel in order to complete the measurement. It includes the evaluation length plus additional lengths at the beginning and end which often must be discarded in the filtering process and are not included when calculating texture parameters.

The image below shows the sampling, evaluation and traversing lengths on a roughness profile. The roughness profile is the result after a short cutoff is applied to the primary profile to remove short spatial wavelength noise, and a long cutoff is applied to remove long spatial wavelength waviness and form. The evaluation length in this case is five sampling lengths. The traversing length includes an additional sampling length at either end which will be discarded prior to analysis.

The key piece of information here is that the sampling length, evaluation length, and traversing length should all be defined based upon the spatial wavelengths that are critical to your part’s performance. This information should all be conveyed on part drawings to ensure that consistent measurement lengths are used, to achieve repeatable roughness measurements.

There is a great deal more to this topic and to specifying, measuring and analyzing surface texture. We invite you to read the rest of this blog to learn more about it. You may also want to learn more about our online and in-person classes to take a deeper dive into surface texture analysis.

Please fill out the form below to download this article as a PDF: