Ra (Roughness Average, or average roughness) is the average height of all measured points on a surface. Ra is the most widely used surface texture parameter. As we’ve mentioned elsewhere in this blog, there is much information about a surface that Ra cannot provide. It can, however, be a fast, simple way to tell whether a surface or a process has changed across time.

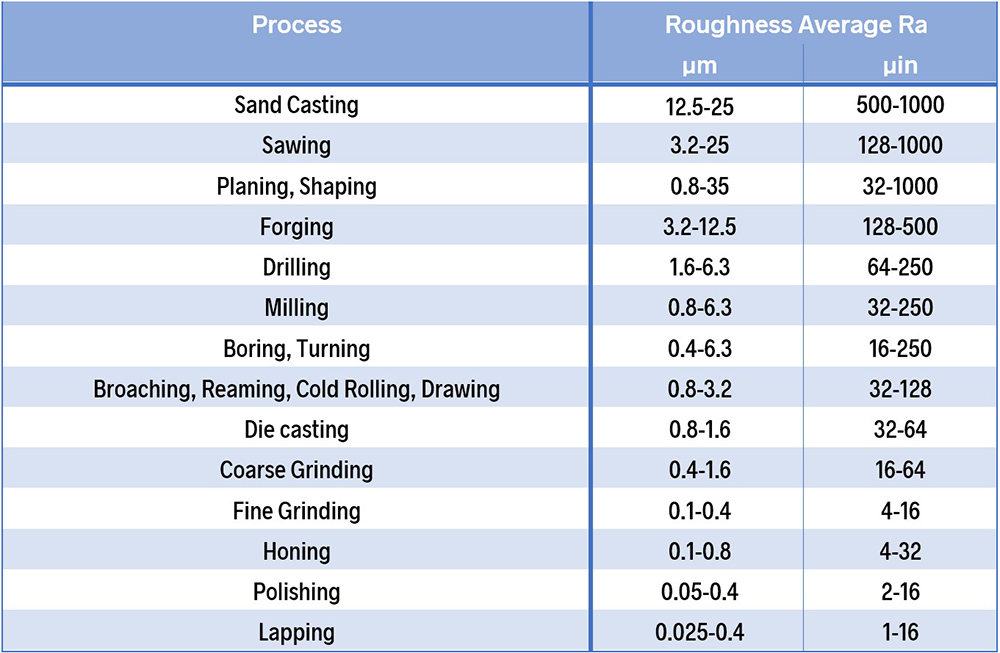

As you consider Ra and surface texture in general, it’s helpful to have a mental image of the kind of surfaces that relate to Ra values. One way to do this is to think in terms of manufacturing processes and the Ra values that they are likely to produce. The chart below shows typical Ra value ranges that you might expect from common manufacturing operations.

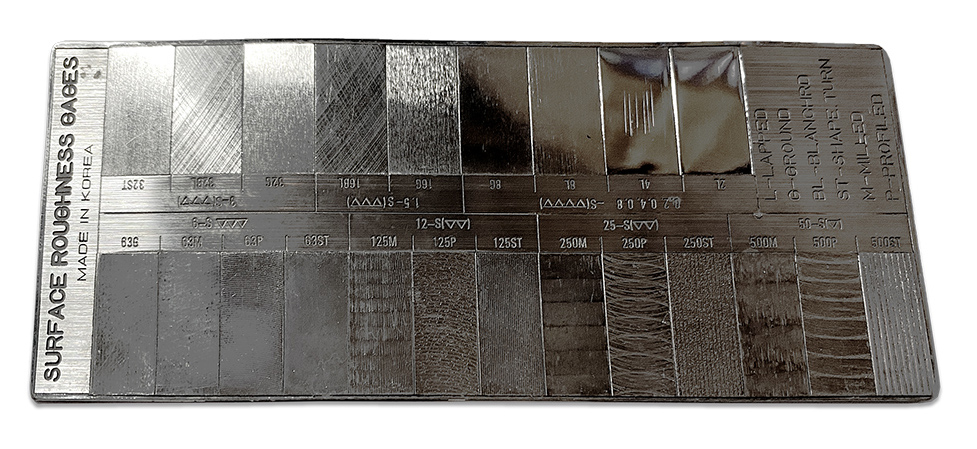

Another useful tool for developing an intuitive sense of Ra values is a tactile gauge, or comparator strip. A tactile gauge contains sample surface finishes that can serve as a first-pass comparison to a measured surface.

Of course there’s very much more to surface texture than Ra and comparators. If you’re interested in a deeper dive, our Surface Texture and Tribology short course includes modules on measurement basics, including instruments, filtering, and parameters, as well as more advanced, application-specific information. All the modules are available on udemy.com and can be reached through our website here. I encourage you to have a look!