Startups, incubators, “skunk works…” when a company is in startup mode, everything is happening at once. Manufacturing processes are being designed while funding is being secured and sales are being closed—all while the product may still be taking shape.

During these critical months, developers need access to accurate measurement data, to push products and processes forward. But dedicated measurement equipment may not be available until much later in the cycle.

So, how can developers verify that their processes will be ready for rollout?

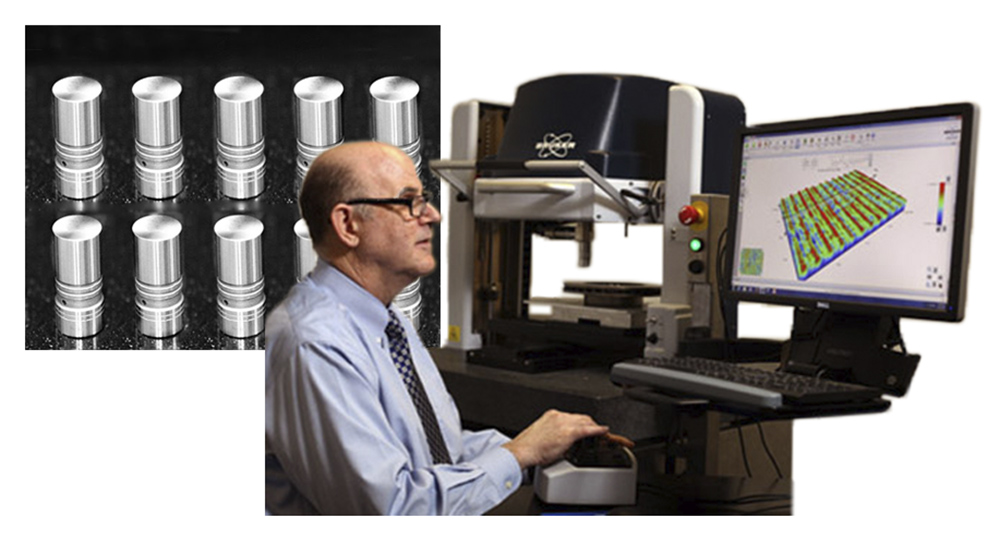

During development, specialized measurement equipment and expertise may not yet be available in-house. Image courtesy Bruker.

Outsourcing measurement capability

Metrology is often one of the last pieces added to the production puzzle. This is, in part, because measurement requirements may not be fully understood until the process is mature. There may also be an incentive to delay capital investments in metrology until the need is completely clear.

In the interim, however, developers still need data.

Many small companies maintain some level of dimensional measurement capability. But more specialized measurement equipment, such as 3D surface roughness measurement systems, is less likely to be available in-house.

Outsourcing measurements to third-party labs offers manufacturers an excellent option to get the data they need without committing to a large capital investment. These measurements can keep development moving until more permanent measurement solutions are available.

Michigan Metrology frequently provides small-batch 3D surface roughness measurements to verify new processes and to troubleshoot product issues. The lab is equipped to accommodate companies’ development schedules, with automation to handle hundreds of parts as well as small samples.

Small batch measurements from a third-party lab can help developers to prove out new processes.

Third-party production measurement can be cost-effective as well

After a product is launched, many companies choose to continue outsourcing measurements rather than incurring the expense to operate an in-house lab. A third-party lab can efficiently measure new parts and report data as a regular, ongoing process step. They can offer expertise as well as equipment, to help solve production or quality issues as well as to measure parts.

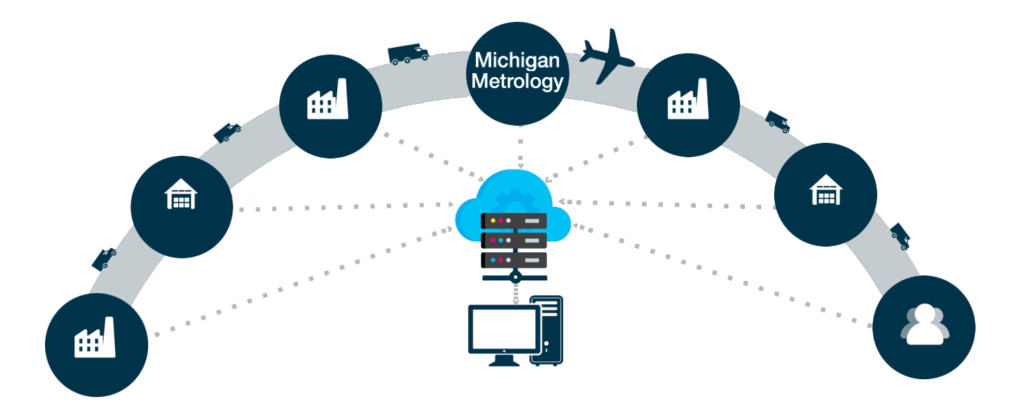

Michigan Metrology maintains measurement arrangements with various regional and national manufacturers. Those companies are able to leverage our 30+ years of 3D surface roughness expertise to continue improving processes after launch. Our location in Livonia makes ground shipments easy throughout the Midwest across the country, enabling us to be a reliable, integral part of supply chains.

The merits of outsourcing extend to larger companies as well as startups and smaller firms. For larger companies, outsourcing often proves to be cost-effective for critical measurements that may exceed their in-house capabilities.

Beyond production measurement

A third-party measurement lab can be much more than just a metrology resource—it can be a partner that helps guide a product from prototype to production. Michigan Metrology is a partner for dozens of small and large manufacturing companies throughout the country.

Whether your development team needs a few measurements to validate a process, ongoing measurements for process control, or a thorough analysis to solve a production or quality challenge, a measurement lab such as Michigan Metrology can provide the equipment and expertise to get you the data you need.

Michigan Metrology provides rapid, 3D surface roughness measurements for development and production.