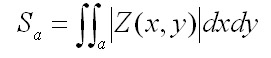

Sa

For the discussions that follow, Z(x,y) is the function representing the height of the surface relative to the best fitting plane, cylinder, or sphere. Note that the “a” used in the following integral expressions implies that the integration is performed over the area of measurement and then normalized by the cross-sectional area “A” of the measurement.

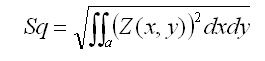

Sa and Sq

Sa and Sq are the Average Roughness and Root Mean Square Roughness are evaluated over the complete 3D surface respectively. Mathematically, Sa and Sq are evaluated as follows:

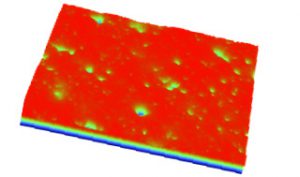

Plateau-like surface Sa = 16.03 nm Sq= 25.4 nm

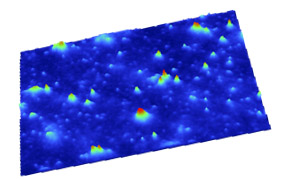

Surface with Peaks Sa = 16.03 nm Sq= 25.4 nm

Application

The Sa and Sq parameters represent an overall measure of the texture comprising the surface. Sa and Sq are insensitive in differentiating peaks, valleys and the spacing of the various texture features. Thus Sa or Sq may be misleading in that many surfaces with grossly different spatial and height symmetry features (e.g., milled vs. honed) may have the same Sa or Sq, but function quite differently. The figure above demonstrates two very different surfaces with identical Sa and Sq values, indicating the insensitivity of the Sa and Sq parameters. Nonetheless, once a surface type has been established, the Sa and Sq parameters may be used to indicate significant deviations in the texture characteristics. Sq is typically used to specify optical surfaces and Sa is used for machined surfaces.

Also see: