High-precision surface texture measurement systems are more widely available now than they were 10 or 15 years ago. Yet, purchasing such systems can still be difficult to justify for small measurement volumes. And, they can be quite expensive when high measurement volumes require some level of automation.

While a capital investment in a machine tool is typically straightforward to justify, making a case for a large metrology investment can be much more challenging. Companies often opt to make do with low-resolution surface texture gauges to avoid a larger purchase.

Outsourcing surface texture measurement is a cost-effective alternative, particularly while a process is being developed. But while quite a few labs provide high-volume GD&T measurement (some even with roughness measurement capabilities), it is much harder to find a source for volume measurement of surface texture. Rarer still are labs with in-house expertise to solve surface texture issues as well as measure parts.

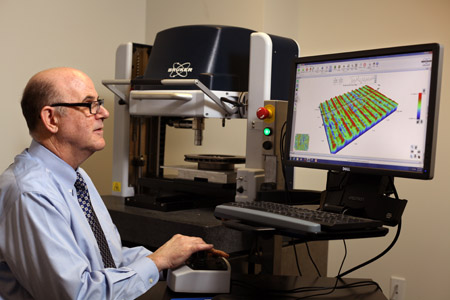

Michigan Metrology, a measurement lab based in Livonia, Michigan, offers 3D surface roughness, texture, finish, and wear measurements on a contract basis. The company provides surface texture analysis to verify and validate processes, to investigate production challenges, and to provide volume production measurement on an ongoing basis. Primary equipment includes 3D optical profilers from Bruker as well as a range of other equipment. Dr. Don Cohen, founder of Michigan Metrology, brings nearly 40 years of metrology expertise to bear to solve challenging production and warranty issues, and to help develop measurements and parameters to support new processes and ensure ongoing quality.

Learn more about Michigan Metrology’s Contract Measurement services.