In this 3-part series we look at the case of dry, sliding friction and discuss how surface roughness and materials impact the surface as a bearing.

PART 3 Plasticity

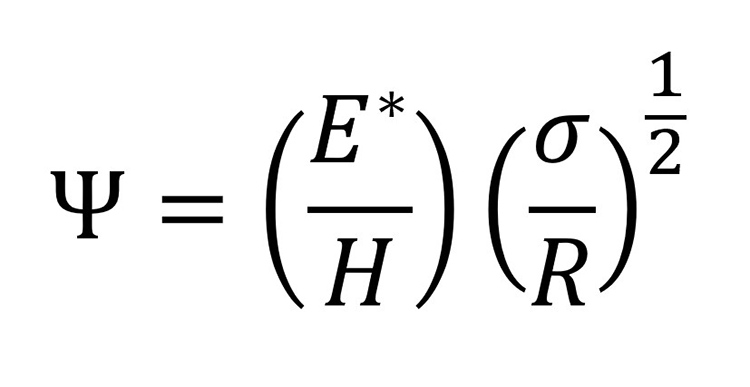

Last week we introduced the “plasticity index”1:

The higher the plasticity, the more likely the surface will be to deform plastically. From the equation, we can see that plasticity increases when:

- we use a material with a larger Modulus (E)

- we use a material with a lower hardness (H)

- the standard deviation of peak heights (σ) is reduced (i.e., the overall roughness is reduced)

- the mean radius of the summits (R) decreases (i.e., the peak material is “sharper”).

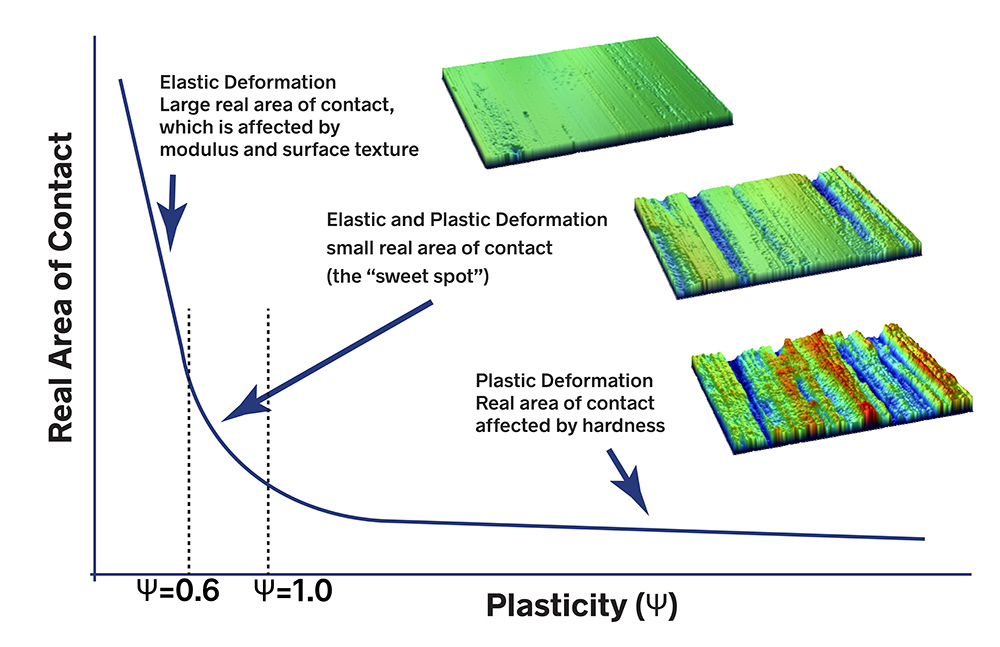

If we plot the real area of contact against plasticity (for a fixed load between the surfaces), we get a curve like the one below.

Real area of contact plotted against plasticity.2

Now, back to bearings. Our primary goals for a bearing are to minimize the real area of contact while also minimizing wear. For the latter, we want to ensure elastic deformation, not plastic deformation.

When Ψ is very small (the left side of the graph), the material will deform elastically…but, the real area of contact will be very high. In a bearing this would cause high friction, perhaps localized welding and galling that could lead to failure.

When Ψ is much larger than 1, the deformation is primarily plastic, and the interface will wear quickly.

When Ψ is between roughly 0.6 and 1.0, the surface will deform both elastically and plastically, ultimately running-in to a state where only elastic deformation occurs. It will also maintain a small real area of contact, making the surface a good candidate for a bearing.

We now have a goal for a bearing, to try to achieve a Ψ value in the “sweet spot” on this curve. For a dry, sliding interface, we may consider different bulk materials, or coatings or treatments that will reduce the shear strength at the real area of contact. We can also alter the surface texture to adjust the surface roughness, and the curvature of the peak material, both of which will change the real area of contact and the Ψ value.

Of course, lubrication will also make a world of difference…but more on that later.

It’s a lot to learn, and even three blog posts is just a start. If you want to go further, check out the Surface Roughness, Texture, and Tribology short course.

References:

- Greenwood, J. A. and Williamson, J.B.P (1966), “Contact of Nominally Flat Surfaces”, Proc.Roy.Soc Lond. A295, 300-319.

- Bharat Bhushan, Introduction to Tribology. John Wiley & Sons Ltd, New York, 2013.

- Frank Philip Bowden and David Tabor, Friction, An Introduction to Tribology, Robert E. Krieger Publishing Co. Malabar, Florida 1973.

- Ernest Rabinowicz, Friction and Wear of Materials, John Wiley & Sons, 1995.

Please fill out the form below to download this article as a PDF: