Sds

Sds (sometimes written Ssd), the Summit Density, is the number of summits per unit area of the surface.

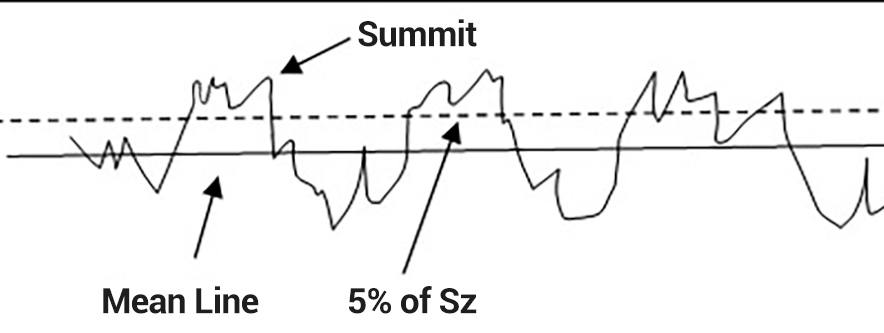

To calculate Sds we find the number of “summits” per unit area of the surface. The summits are derived from “peaks,” which are defined as any point that is higher than all 8 of its nearest neighbors. When we calculate Sds we consolidate closely spaced peaks into a single summit. We also only include summits that exceed a height threshold above the mean plane (i.e., only summits that are likely to contact a mating surface). These constraints help remove noise and outliers so that we have a more repeatable measure of the density of high areas of the surface.

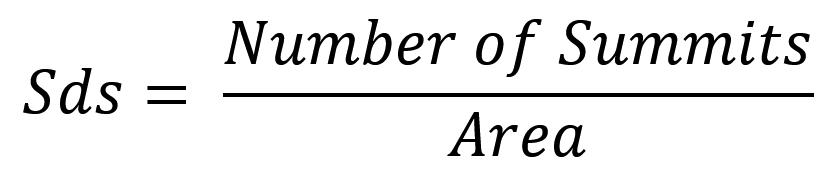

Sds is then calculated as:

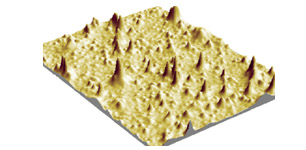

Surface with Sds ~ 2600 summits/mm.

Note that Sds is not strictly defined in the ISO 25178-2 but was established earlier in the research which contributed to ISO 25178-2. Future sections of ISO 25178-2 may address parameters such as Sds as “Feature Parameters”.

Real Area of Contact

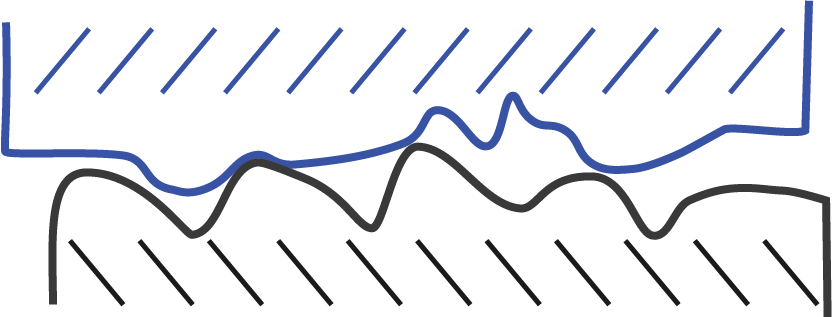

To understand how the surfaces interact, we need to understand the “real area of contact” between the two surfaces. When surfaces are in contact not all points are in contact:

Therefore, we need parameters that can describe how much of the surfaces actually are touching, and the shape of those areas that are making contact. Sds (the Summit Density) counts the number of summits per unit area of the surface. It is often used in conjunction with Ssc (the Mean Summit Curvature) which is an indicator of the shape and size of the higher areas of a surface.

Application

Sds is a key parameter when considering surfaces used in applications such as bearings, seals and electronic contacts. The manner in which the summits elastically and plastically deform under load is related to the Sds parameter. Depending on the application, a low Sds may result in higher localized contact stresses resulting in possible pitting and debris generation. In applications involving sliding components, a number of summits are needed to prevent optical contacting while maintaining a reasonable load distribution. Summit density may also be related to the cosmetic appearance of a surface once painted.

For bearing surfaces, such as in this medical device, the nature of the texture matters as well as the amplitude. Parameters such as Summit Density (Sds) and Mean Summit Curvature (Ssc) provide a clearer prediction of friction and wear.

For more on Sds and its usage, see the blog article, Using Ssc and Sds to understand how surfaces interact and wear.

Read about Sds and Ssc as they relate to medical devices in the blog article, What surface finish does a medical device need?