For a medical device to function over a long lifespan, we need to accurately specify, measure, and control its surface finishes. Yet, most surface finish specifications rely on parameters that give little information about the aspects of texture that will actually impact how the device will function. In this post we’ll look at the kinds of surface texture considerations that we need to make in order to produce quality medical devices with excellent longevity.

Surface texture is more than “roughness“

The term “roughness” is often used to refer to surface texture—but this can be misleading. Roughness suggests a consistent, unchanging profile across the surface, while in reality microscopic texture consists of all kinds of shapes, including flat regions, sharp and rounded peaks, valleys, porosity, tool marks, scratches, etc.

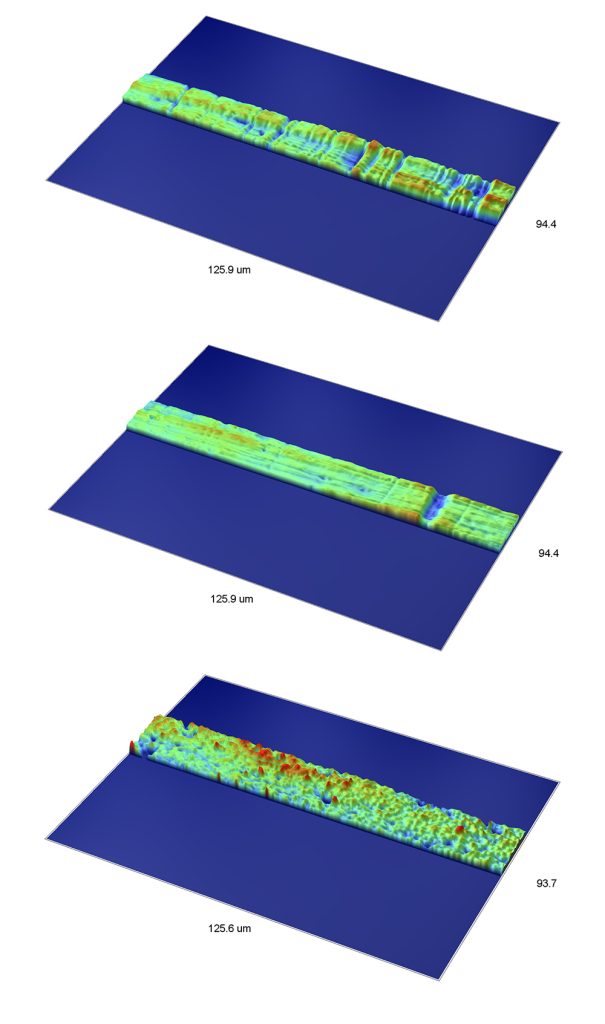

Most surface finish specifications only call out a single roughness parameter, such as average roughness (Ra, or Sa) or average maximum height (Rz, or Sz). While parameters like these can be useful for spotting changes in processes, they only provide general information about the surface. Tracking a process based on Ra or Rz alone is like trying to diagnose an illness by only measuring a patient’s temperature. A fever may indicate a simple infection, but it could also point to a serious disease. More, and better, information is needed to accurately diagnose the issue. The image below shows three optical profiler surface measurements. In the top surface, the strong texture in one direction may provide consistent fluid flow. The polished sample in the center has a deep notch which could lead to fatigue failure. In the bottom image, the non-directional texture may be desired for coating adhesion. Yet, if we only measure average roughness, these three surfaces will appear identical!

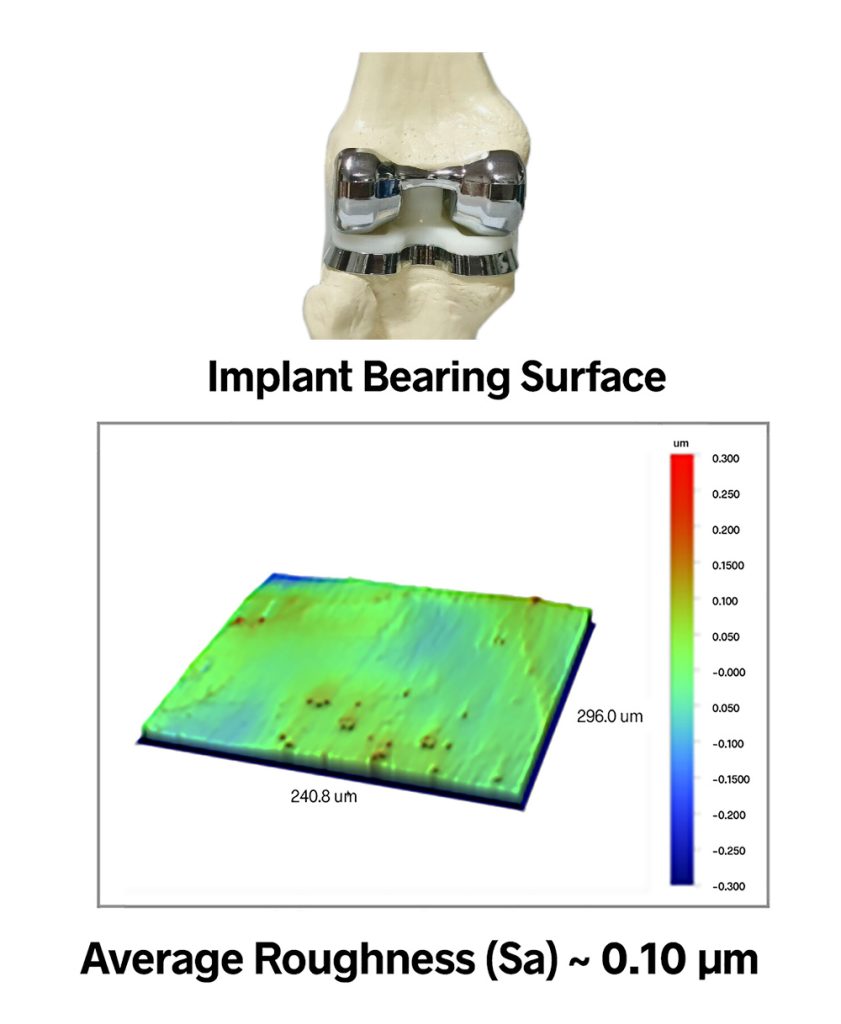

Bearing surfaces

How well a medical device will perform often depends on some particular aspect of surface texture. For example, the bearing surfaces in replacement joints are often polished to a mirror finish. Instinctually, a polished surface seems like it would provide the least friction and therefore the best wear. In practice, however, the “best” finish depends on the application. For joints that retain sufficient synovial fluid, smooth bearing surfaces are indeed best. However, when components are rubbing directly against each other with little lubrication, then the bearing surfaces must have some degree of texture to reduce the real area of contact and to retain the small amount of available lubricant.

The nature of that texture matters as well. Parameters such as Mean Summit Curvature (Ssc), Summit Density (Sds) provide a clearer prediction of friction and wear. Parameters derived from the bearing area curve and tribology parameters are also good predictors of friction and wear.

The surface of this implant has been polished to a mirror finish. But is this the best surface for the component?

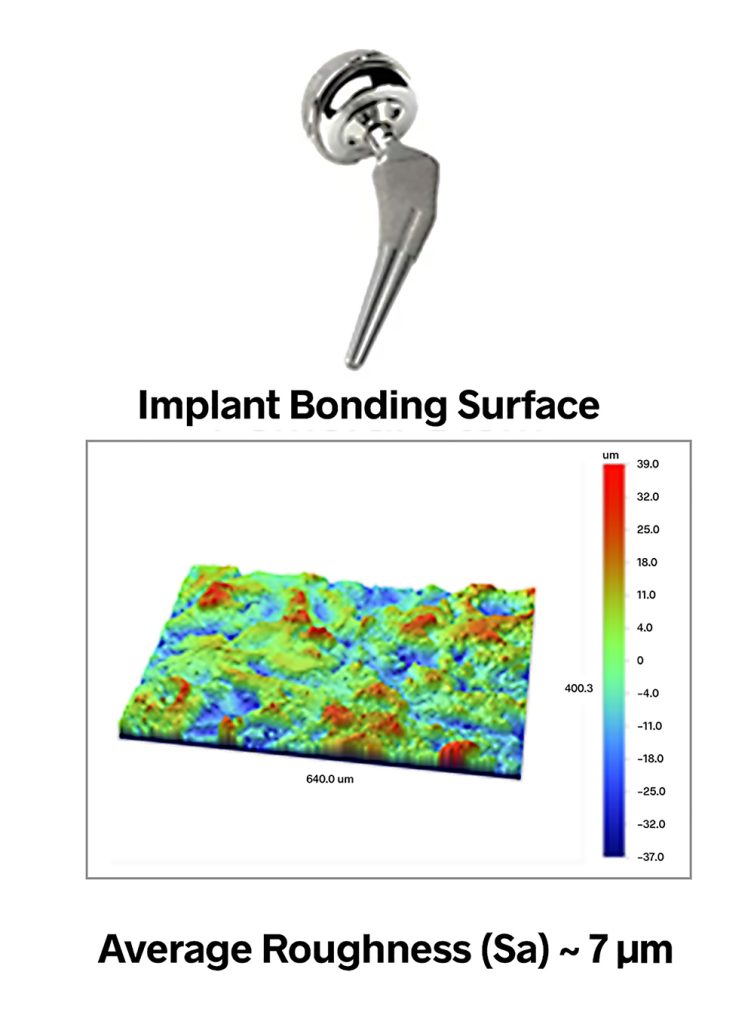

Bonding surfaces

While bearing surfaces need to be smooth, the bonding areas of replacement joints must be rough. However, it’s not sufficient to simply roughen up the surface. Again, the nature of the texture matters. Any directionality (“lay”) in the texture could lead to slipping or swiveling of the joint, so non-directional texture may assist with long-term bonding. Particular heights and spacings of texture features may promote optimum bone growth. The Developed Interfacial Area Ratio (Sdr) parameter provides information about available surface area that can lead to better adhesion control.

The bonding areas of an implant have much higher roughness than the bearing areas.

Measuring finish on complex surfaces

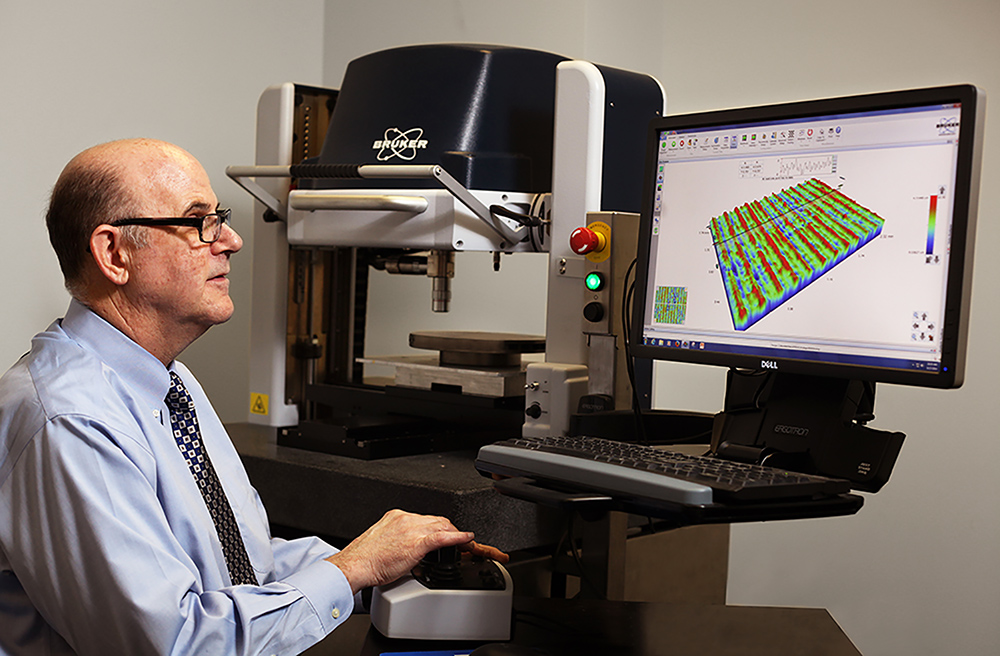

Complex surface shapes, such as the small, highly curved features of a spinal implant, may be extremely challenging to measure with a traditional stylus. Non-contact 3D optical profilers, such as the one shown below, are well-suited to these kinds of measurements. Long working distance, large vertical range, and the option to use mirrors to guide the measurement beam make it possible to measure highly curved surfaces and otherwise inaccessible features.

An optical profiler provides high resolution, 3D measurement of complex surface shapes.

Surface finish for fluid flow

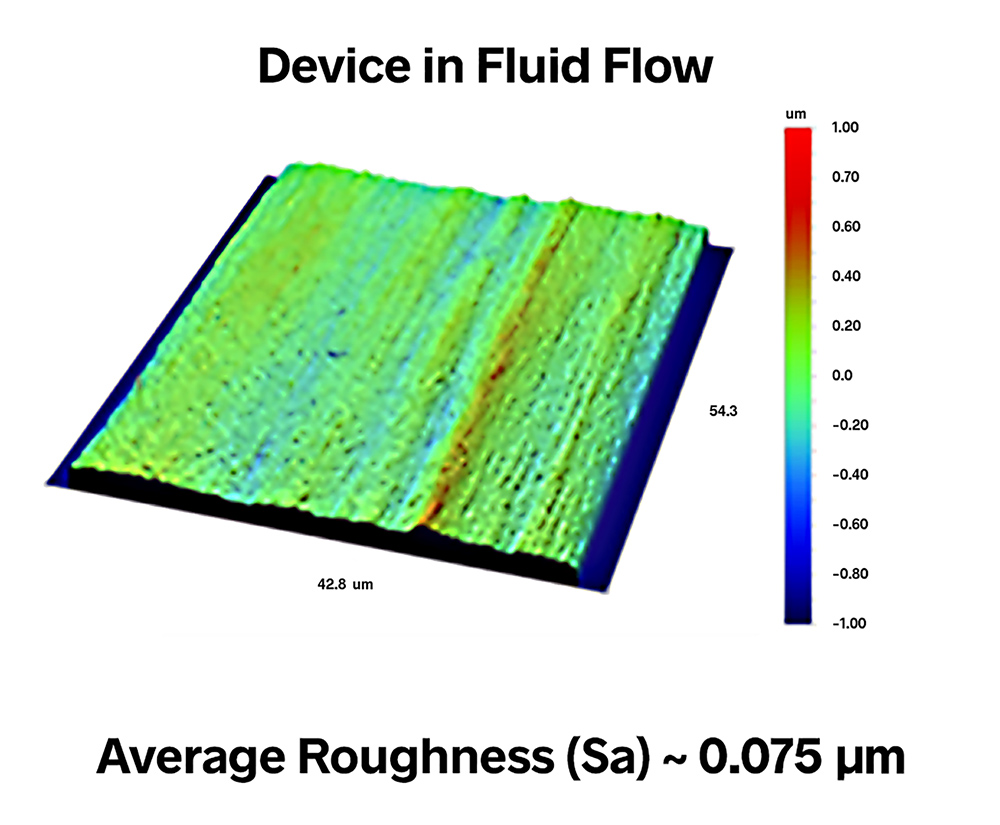

The surface finish for cardiac and arterial devices must be smooth to avoid turbulent flow and to prevent thrombosis and clot formation. The scale of the texture that is important in this case, however, may not be the scale of the blood cells. The proteins that initiate clotting interact with more finely spaced, lower amplitude texture, so the smoothest finishes (often less than 100nm Sa) are often best for devices in the blood flow. Smooth finishes also prevent damage to blood cells from processes such as hemolysis as the cells are forced through constrictions.

The texture of a device associated with blood flow is extremely smooth to inhibit clotting processes.

The surface texture of medical devices is fundamental to their function. By specifying and controlling the right set of parameters we can optimize the component’s surface to increase performance, wear life, and safety.

Want to learn more? The upcoming Surface Roughness, Texture, and Tribology 2-day class is a fantastic way to immerse yourself in surface measurement, tribology, and related topics.

Please fill out the form below to download this article as a PDF: