3D Hybrid Parameters

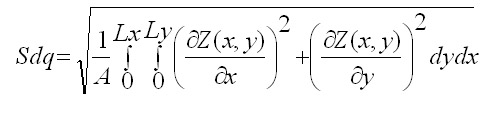

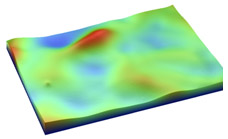

Sdq (Root Mean Square (RMS) Surface Slope)

Sdq is the Root Mean Square (RMS) Surface Slope comprising the surface, evaluated over all directions.

Application

Sdq is a general measurement of the slopes which comprise the surface and may be used to differentiate surfaces with similar average roughness, Sa. Sdq may find application for sealing systems, surface cosmetic appearance and may be related to the degree of surface wetting by various fluids. Sdq is affected both by texture amplitude and spacing. Thus for a given Sa, a wider spaced texture may indicate a lower Sdq value than a surface with the same Sa but finer spaced features, as demonstrated above.

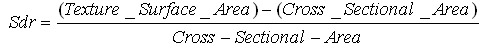

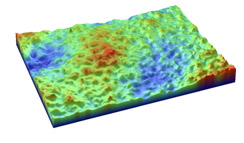

Sdr (Developed Interfacial Area Ratio)

Sdr, the Developed Interfacial Area Ratio, is expressed as the percentage of additional surface area contributed by the texture as compared to an ideal plane the size of the measurement region.

Application

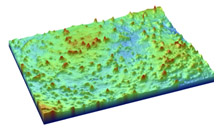

Sdr may further differentiate surfaces of similar amplitudes and average roughness. Typically Sdr will increase with the spatial intricacy of the texture whether or not Sa changes. Sdr is useful in applications involving surface coatings and adhesion. Sdr and may find relevance when considering surfaces used with lubricants and other fluids. Sdr is affected both by texture amplitude and spacing. Thus higher Sa, wider spaced texture may have actually a lower Sdr value than a lower Sa but finer spaced texture, as displayed above.

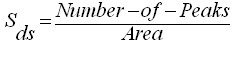

Sds (Summit Density)

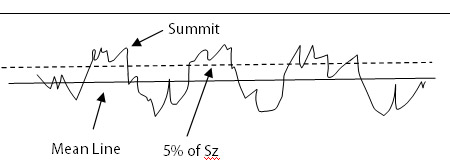

Sds, the Summit Density, is the number of summits per unit area making up the surface. Summits are derived from peaks. A peak is defined as any point, above all 8 nearest neighbors. Summits are constrained to be separated by at least 1% of the minimum “X” or “Y” dimension comprising the 3D measurement area. Additionally, summits are only found above a threshold that is 5% of Sz above the mean plane.

(Note that Sds is not strictly defined in the ISO 25178-2 but was established earlier in the research which contributed to ISO 25178-2. Future sections of ISO 25178-2 may address parameters such as Sds as “Feature Parameters”.)

Application

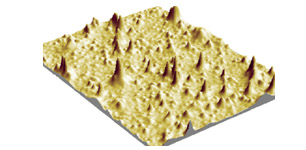

Sds is a key parameter when considering surfaces used in applications such as bearings, seals and electronic contacts. The manner in which the summits elastically and plastically deform under load is related to the Sds parameter. Depending on the application, a low Sds may result in higher localized contact stresses resulting in possible pitting and debris generation. In applications involving sliding components, a number of summits are needed to prevent optical contacting while maintaining a reasonable load distribution. Summit density may also be related to the cosmetic appearance of a surface once painted.

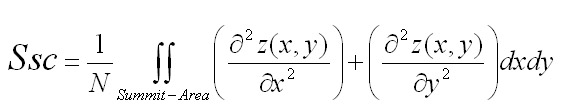

Ssc (Mean Summit Curvature)

Ssc is the Mean Summit Curvature for the various peak structures. Peaks are found as described above for the summit density. Ssc is given by the following:

(Note that Ssc is not strictly defined in the ISO 25178-2 but was established earlier in the research which contributed to ISO 25178-2. Future sections of ISO 25178-2 may address parameters such as Sds as “Feature Parameters”.)

Application

Ssc is useful in predicting the degree of elastic and plastic deformation of a surface under different loading conditions and thus may be used in predicting friction, wear and real area of contact for thermal/electrical applications.