The scale of interaction

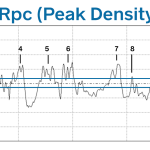

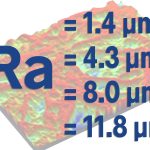

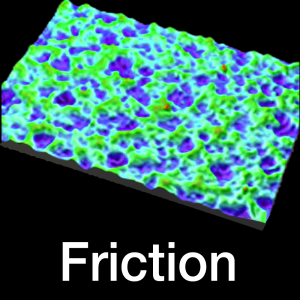

I live in a world that is 1 mm x 1mm, and often less than 20µm high. It’s amazing, all of the physics that goes on in such a tiny area! Faced with a production or quality issue, people regularly send parts and want us to measure the entire part surface with our 3D optical … Read more