Which feature size scales matter for coating adhesion?

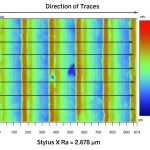

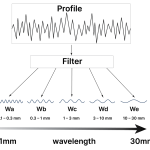

When it comes to coatings, the amount of surface area matters. We know that increasing the surface area can improve adhesion, and that “roughing up” a surface increases surface area. But is all “roughness” equal when it comes to making coatings stick? Surface area Surface area impacts how well a coating will adhere, how well … Read more