Welcome to the Surface Roughness Analysis Blog

Why do brakes squeak? When will a gasket leak? What caused the haziness in my painted finish?

Surface texture and function are tightly linked. Understanding the relationship between texture and function, and sharing that information with engineers and quality professionals, is what Michigan Metrology is all about.

The articles in this blog explore the concepts of surface texture analysis and measurement. We show how you can apply these concepts to solve problems related to leaks, squeaks, appearance, wear, noise, fit, friction, vibration, adhesion, and many other functions.

Looking for more information on specific surface texture parameters? Visit our Surface Texture Parameters Glossary for an introduction to dozens of 3D surface roughness analysis parameters.

And, if you want to learn much more about surface texture consider attending our online and in-person classes for an immersive introduction to the many concepts in surface analysis.

Traversing length, evaluation length and sampling length

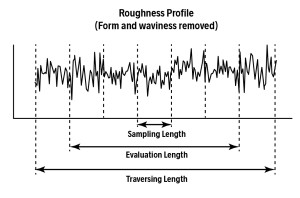

March 16, 2022Download this article as a PDF When measuring roughness with a stylus-based system you’ll hear the terms “traversing length,” “evaluation length” and “sampling length.” It’s important to understand their specific

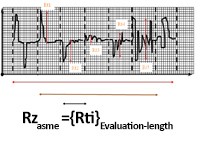

When Rz isn’t Rz

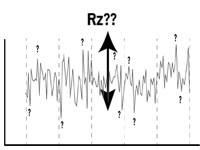

March 9, 2022Download this article as a PDF Rz is always Rz…isn’t it? Usually, but not necessarily. Rz, the average maximum surface height, is one of the most widely used surface texture parameters.

Quality 101: Texture Measurements – Quality Magazine

March 7, 2022…Modern metrology instruments, methods and surface texture parameters have made it possible to describe, in great detail, the functionally important features of a surface’s texture. A key aspect of surface

Average Roughness basics

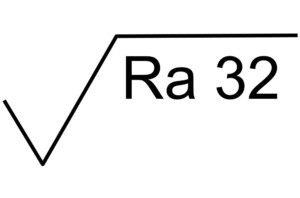

January 23, 2021How do I measure Ra 32? or 32 Ra? or 32? Download this article as a PDF Average roughness (Ra) is the tip of the deep and complex world of

Multiscale surface texture analysis in action

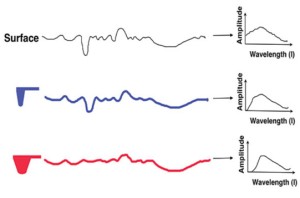

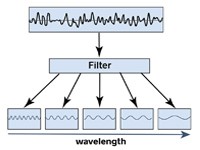

December 20, 2020Paint appearance is critical to the perception of quality, particularly in consumer goods such as automobiles. We’ve written frequently in this blog about surface texture consisting of a spectrum of

When wear looks like filtering (and vice versa)

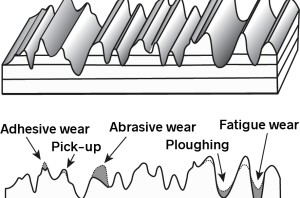

November 19, 2020Wear between two surfaces in contact can take the form of mechanisms such as ploughing, abrasion, adhesion, fatigue, etc. The initial phase of a component’s life will involve some period

Using Ssc and Sds to understand how surfaces interact and wear

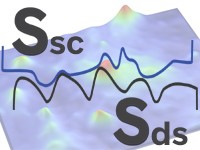

October 18, 2020When surfaces move against each in contact, we need to understand how the surfaces interact, how much friction is involved, and how they will wear in response to the contact.

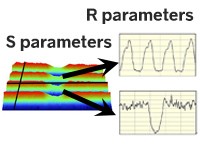

Making the change from R Parameters to S Parameters

September 17, 2020We are commonly asked to clarify the differences between R and S surface roughness parameters. This often comes up when someone begins working with a new instrument, part or process

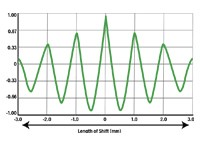

Parameters Primer: ACF (Autocorrelation Function)

August 16, 2020The autocorrelation function (ACF) is a measure of how random or periodic a surface is. ACF is found by creating a duplicate of the surface, then shifting the duplicate relative

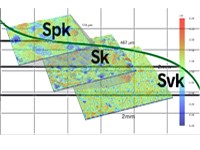

Analyzing steel clutch reaction plates

July 15, 2020Applying the Material Ratio parameters — case study In our post of a few weeks ago we discussed the Stylus (X,Y) parameters, which are derived from the 2D Bearing Ratio

Surface texture measurement – Ra, Rz, Rmax, Rz1max, Maximum Height

June 22, 2020This article discusses several key surface texture measurement parameters: average roughness (Ra), average maximum surface height (Rz), maximum of all per-sampling-length peak-to-valley heights (RMax), and the Maximum Height (Rz1max). We

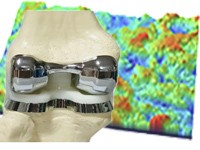

Surface finish for medical devices

June 14, 2020Artificial medical devices prolong life and preserve quality of living. To design devices that will function reliably and safely for decades requires careful attention to materials and surface finish. Accurately